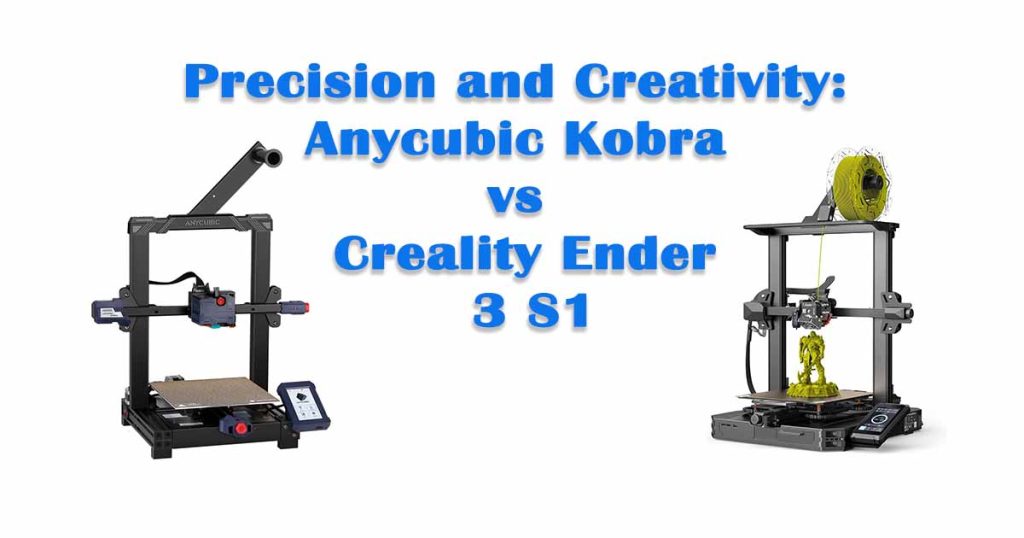

In the ever-evolving world of 3D printing, two giants have emerged to redefine the landscape – Anycubic Kobra and Creality Ender 3 S1. These two printers have sparked a revolution, making it easier and more accessible for enthusiasts and professionals alike to bring their creative visions to life.

But with such a rapidly expanding market, how do you choose the right 3D printer for your needs? That’s where this comprehensive comparison comes in.

In this article, we will delve deep into the intricacies of the Anycubic Kobra and the Creality Ender 3 S1. We will explore their key features, print quality, ease of use, software compatibility, and much more.

By the end, you’ll have a clear understanding of which printer aligns best with your specific requirements, whether you’re a hobbyist seeking a budget-friendly option or a professional in pursuit of precision.

Design and Build Quality

When comparing 3D printers like the Anycubic Kobra and the Creality Ender 3 S1, one crucial aspect to consider is their design and build quality. Both machines offer unique features, but the Anycubic Kobra stands out with its robust and innovative design.

Its metal frame ensures stability and precision during printing, reducing the chances of structural issues. The Kobra’s modular design also makes it easy to assemble and maintain.

On the flip side, the Creality Ender 3 S1 stands out in the world of 3D printers due to its impeccable build quality. Crafted with a robust aluminum frame, it excels in reducing vibrations, resulting in impeccably smooth prints. However, for those seeking more insights into Creality 3D printers and comprehensive guidance, we recommend checking out the detailed reviews and recommendations in our Creality 3D Printer Guide. While the assembly process may pose a minor challenge for some users, our guide can provide valuable assistance in making the most of your Creality 3D printer experience.

Ultimately, the choice between these two 3D printers will depend on your preferences for design and build quality, with both models offering their distinct advantages.

Print Volume and Bed Size

When it comes to 3D printing, two key factors that enthusiasts and creators often consider are print volume and bed size. In the battle of Anycubic Kobra vs Creality Ender 3 S1, these aspects play a pivotal role in decision-making.

The Anycubic Kobra boasts an impressive print volume, allowing for larger and more intricate creations. Its generous bed size accommodates projects of various scales, opening up a world of possibilities for ambitious makers.

On the other hand, the Creality Ender 3 S1 offers a more compact build area, which might be ideal for those with limited workspace. Ultimately, the choice between these 3D printers depends on your specific needs and the size of your envisioned projects.

Whether you prioritize spaciousness or space-saving, both options offer reliable performance, emphasizing the importance of aligning your choice with your creative objectives.

Print Quality and Accuracy

When it comes to 3D printing, two crucial factors that significantly impact print quality and accuracy are print volume and bed size. The print volume refers to the maximum size of an object that a 3D printer can create in a single build.

A larger print volume allows for the fabrication of more substantial and complex designs, but it also demands precise calibration to maintain accuracy across the entire build area. Bed size, on the other hand, pertains to the dimensions of the printer’s build platform.

A spacious bed provides ample room for larger projects, enhancing versatility, but it too must be leveled and heated uniformly to ensure impeccable print quality.

Striking the right balance between print volume and bed size is essential for achieving high-quality and accurate 3D prints, as these factors directly impact the printer’s ability to reproduce intricate details and maintain dimensional precision throughout the entire object.

Filament Compatibility

When it comes to achieving superior print quality and accuracy in the world of 3D printing, one crucial factor often overlooked is filament compatibility. The choice of filament material can significantly impact the final outcome of your 3D prints.

Different filaments, such as PLA, ABS, PETG, and more, have distinct properties and behaviors during the printing process. It’s imperative to select a filament that aligns with your project’s specific requirements.

Filament compatibility ensures proper extrusion, adhesion, and layer bonding, ultimately affecting the final product’s strength, appearance, and precision. Experimentation and fine-tuning with various filaments and settings are essential to achieve the desired print quality and accuracy.

By understanding filament compatibility, 3D printing enthusiasts and professionals can unlock the full potential of their printers and create exceptional, precise objects with ease.

Assembly and Setup

When it comes to achieving impeccable print quality and accuracy, the assembly and setup of your printing equipment play a pivotal role. A meticulous assembly process ensures that all components are precisely aligned, minimizing the risk of misprints and ensuring consistent output.

Calibration of the printer’s settings is equally essential, as it fine-tunes parameters such as resolution, color balance, and layer height to match the desired output.

A well-organized setup also involves selecting the right materials and maintaining a controlled environment to prevent warping and distortion.

In essence, the journey to superior print quality and accuracy commences with the careful assembly and setup of your printing apparatus, laying the foundation for stunning, error-free results that meet the highest standards of precision and clarity.

User Interface and Control

When it comes to print quality and accuracy, the user interface and control systems play a pivotal role in ensuring the desired results. A well-designed user interface empowers operators to fine-tune printing parameters with precision, allowing for adjustments in resolution, color management, and alignment.

Intuitive controls make it easier to navigate through complex settings, reducing the likelihood of errors that could compromise print quality. Moreover, real-time monitoring and feedback mechanisms provided by modern user interfaces enable operators to address issues promptly, ensuring that prints meet the highest standards of accuracy.

In essence, the synergy between print quality and user interface/control is undeniable, as it empowers users to achieve the utmost precision and consistency in their printing endeavors, whether in the realm of professional graphics or everyday document production.

Software Compatibility

When it comes to achieving optimal print quality and accuracy, software compatibility plays a pivotal role in the process. Software compatibility refers to the seamless integration and interaction between the software used for designing and formatting documents and the printers responsible for bringing those designs to life on paper.

Incompatibilities between software and printers can lead to a range of issues, from distorted graphics to misaligned text, compromising the overall print quality and accuracy. To ensure crisp and precise prints, it is crucial to choose software that is fully compatible with your printer’s specifications.

This harmonious synergy between software and hardware not only enhances the final output but also minimizes wastage of time and resources. In the realm of printing, software compatibility is the linchpin that guarantees a flawless execution of your creative visions.

Noise Levels

When it comes to achieving optimal print quality and accuracy, software compatibility plays a pivotal role in the process. Software compatibility refers to the seamless integration and interaction between the software used for designing and formatting documents and the printers responsible for bringing those designs to life on paper.

Incompatibilities between software and printers can lead to a range of issues, from distorted graphics to misaligned text, compromising the overall print quality and accuracy. To ensure crisp and precise prints, it is crucial to choose software that is fully compatible with your printer’s specifications.

This harmonious synergy between software and hardware not only enhances the final output but also minimizes wastage of time and resources. In the realm of printing, software compatibility is the linchpin that guarantees a flawless execution of your creative visions.

Price and Value for Money

When it comes to evaluating the price and value for money in the world of printing, one cannot underestimate the pivotal role played by print quality and accuracy. These two factors are like the compass that guides consumers through the labyrinth of choices in the printing market.

Price alone may lure buyers with promises of affordability, but it’s the quality and precision of the final print that truly determines the value received. A budget-friendly printer might seem like a steal, but if it sacrifices print accuracy and quality, it could lead to costly reprints, frustration, and ultimately a dent in one’s pocket.

Therefore, savvy consumers understand that investing in a printer that balances cost-effectiveness with superior print quality and accuracy ensures not only a satisfying purchase but also long-term savings.

In the realm of printing, price and value are indeed interconnected, with print quality and accuracy serving as the bridge that aligns them harmoniously.

Community and Support

When it comes to print quality and accuracy, community and support play pivotal roles in ensuring excellence. In today’s dynamic printing landscape, professionals and enthusiasts alike rely on a robust support system within their communities to achieve impeccable results.

Whether it’s the world of 3D printing, graphic design, or traditional printing methods, the exchange of knowledge and experiences fosters an environment where individuals can troubleshoot issues, refine techniques, and push the boundaries of precision.

Moreover, community-driven forums, workshops, and online platforms empower enthusiasts to access invaluable insights and guidance from peers and experts.

The synergy between print quality, accuracy, and a strong, supportive community not only elevates the overall printing standards but also nurtures a sense of camaraderie and collective growth among those passionate about the craft.

Conclusion

In essence, the print community’s support is the cornerstone of achieving unparalleled excellence in the realm of print quality and accuracy.

In the battle of Anycubic Kobra vs. Creality Ender 3 S1, the choice ultimately comes down to your specific needs and preferences. The Kobra excels in design, print quality, ease of assembly, user interface, and noise levels. It’s a versatile and reliable option for both beginners and experienced users, with a slightly higher price tag to match its features.

On the other hand, the Creality Ender 3 S1 shines in affordability, a larger build volume, and an extensive user community. It’s an excellent entry point into the world of 3D printing, offering good value for money, although it may require some tinkering and modifications for optimal performance.

Choosing between the Anycubic Kobra and Creality Ender 3 S1 hinges on your priorities. If you prioritize print quality, a modern user interface, and a quieter working environment, the Kobra is the clear winner. However, if you

‘re on a budget and value a larger build volume, the Ender 3 S1 remains an attractive option.

Ultimately, both printers have their strengths and weaknesses, and the right choice depends on your specific requirements and how much tinkering you’re willing to do. Whichever you choose, rest assured that both the Anycubic Kobra and Creality Ender 3 S1 represent excellent options in the ever-evolving world of 3D printing.