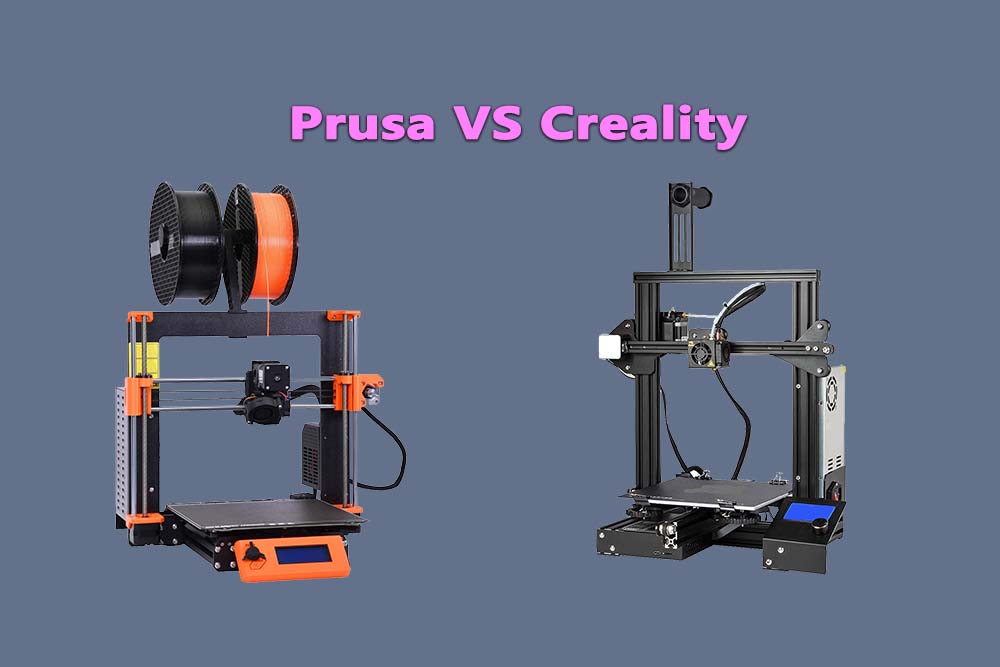

What is Prusa?

Prusa is an open-source 3D printer manufactured by Prusa Research. It was the first 3D printer to use fused deposition modeling.

The printer is made of metal and plastic parts that can be printed using a 3D printer. The Prusa Mendel I3 was released in 2012, and the Prusa i3 MK2 was released in 2016.

What is Creality?

Creality is a Chinese manufacturer of 3D printers. The company produces a range of 3D printers, including the CR-10, CR-10S, Ender 3, and Ender 5. Creality also manufactures filament for 3D printing. The company has a large online following and has been praised for its low-cost 3D printers.

Comparison of Electronics:

The electronics of the Prusa and Creality 3D printers are quite different. The Prusa uses Arduino Mega 2560, while the Creality uses a 24-bit AVR Atmel microcontroller. The Prusa has a heated bed, while the Creality does not.

The Creality also has an LCD screen, which the Prusa does not. The Creality appears to have better build quality, while the Prusa is easier to upgrade. Overall, the two 3D printers are quite different in their electronics and construction.

Comparison of Hardware:

The hardware of the Prusa and Creality 3D printers is quite different. The Prusa uses a single-extruder, while the Creality uses a dual-extruder. The Prusa has an MK10 extruder, while the Creality has an MK8 extruder. The Prusa has a 210x210x200mm build volume, while the Creality has a 300x300x400mm build volume.

The Prusa has a Y-axis belt drive, while the Creality has a X-axis belt drive. The Creality also has an LCD screen, which the Prusa does not. Overall, the two 3D printers are quite different in their hardware and construction.

Comparison of Software:

The software of the Prusa and Creality 3D printers is quite different. The Prusa uses Slic3r, while the Creality uses Cura. The Prusa has a more complex interface, while the Creality is more user-friendly.

The Prusa also allows for more customization, while the Creality is more limited in its options. Overall, the two 3D printers have different software that affects their usability and functionality.

Comparison of Mechanics:

The mechanics of the Prusa and Creality 3D printers are quite different. The Prusa has a 2020 aluminum frame, while the Creality has a 2020 steel frame. The Prusa uses linear bearings on the X and Y axes, while the Creality uses ball bearings.

The Prusa has a Z-axis lead screw, while the Creality has a Z-axis threaded rod. Overall, the two 3D printers have different mechanics that affect their quality and performance.

Comparison of Motherboard:

The motherboard is a very important part of a 3D printer. It controls all the other components, and it can affect the quality and performance of the printer. The motherboard of the Prusa and Creality are quite different. The Prusa uses an Arduino Mega 2560, while the Creality uses a 24-bit AVR Atmel microcontroller.

The Arduino Mega 2560 is a more complex and powerful motherboard than the microcontroller used in the Creality. This may be why the Prusa is able to print at higher resolutions than the Creality. Additionally, the heated bed on the Prusa is controlled by the motherboard, while the heated bed on the Creality is not.

This difference may also account for the differences in printing quality between the two 3D printers. Ultimately, the motherboard is an important component that affects the overall quality and performance of a 3D printer.

Comparison of heated bed:

The heated bed on the Prusa is controlled by the motherboard, while the heated bed on the Creality is not. This difference may account for some of the differences in printing quality between the two 3D printers.

The Prusa has a more complex motherboard than the Creality, which may be why it is able to print at higher resolutions than the Creality. Additionally, the heated bed on the Prusa is larger than the heated bed on the Creality. This may help to prevent warping of larger printed objects.

Comparison of Extruder:

The extruder is another important component of a 3D printer. It is responsible for melting the plastic and depositing it on the print bed. The extruder of the Prusa and Creality are quite different. The Prusa uses an MK10 extruder, while the Creality uses an MK8 extruder.

The MK10 extruder has a longer nozzle than the MK8 extruder, which may help to reduce clogging. Additionally, the MK10 extruder has a geared drive, while the MK8 extruder does not. This may help to increase the torque and reduce the chance of stripping gears.

Ultimately, the extruders of the Prusa and Creality are quite different, and they each have their own advantages and disadvantages.

Comparison of Filament:

The filament is another important component of a 3D printer. It is the material that is melted and deposited on the print bed to create the object. The filament of the Prusa and Creality are quite different. The Prusa uses 1.75mm ABS or PLA filament, while the Creality uses 3.0mm PLA filament.

The thicker filament of the Creality may help to reduce clogging and improve printing quality. Additionally, the Creality has a heated build platform, which may help to prevent warping of larger printed objects.

Ultimately, the filament of the Prusa and Creality are quite different, and they each have their own advantages and disadvantages.

Comparison of Firmware:

The firmware is another important component of a 3D printer. It controls all the other components, and it can affect the quality and performance of the printer. The firmware of the Prusa and Creality are quite different.

The Prusa uses an open-source firmware based on Marlin, while the Creality uses a closed-source firmware. The open-source firmware of the Prusa may be more customizable and easier to modify than the closed-source firmware of the Creality.

Additionally, the Creality has a proprietary file format for printing objects, while the Prusa does not. This difference may make it difficult to share files between printers.

The MK10 extruder has a longer nozzle than the MK8 extruder, which may help to reduce clogging. Additionally, the MK10 extruder has a geared drive, while the MK8 extruder does not. This may help to increase the torque and reduce the chance of stripping gears.

Ultimately, the firmware of the two printers are quite different. In conclusion, the Prusa and Creality are quite different in many ways, and each has its own advantages and disadvantages.

FAQ’s:

Q: What is the difference in the heated beds between the Prusa and Creality?

A: The heated bed on the Prusa is larger than the heated bed on the Creality. This may help to prevent warping of larger printed objects.

Q: What is the difference in the extruders between the Prusa and Creality?

A: The extruder of the Prusa uses an MK10 extruder, while the Creality uses an MK8 extruder.

Q: What is the difference in the filaments between the Prusa and Creality?

A: The filament of the Prusa is 1.75mm ABS or PLA filament, while the Creality uses 3.0mm PLA filament.

Q: What is the difference in the firmware between the Prusa and Creality?

A: The firmware of the Prusa is open-source based on Marlin, while the Creality uses a closed-source firmware.