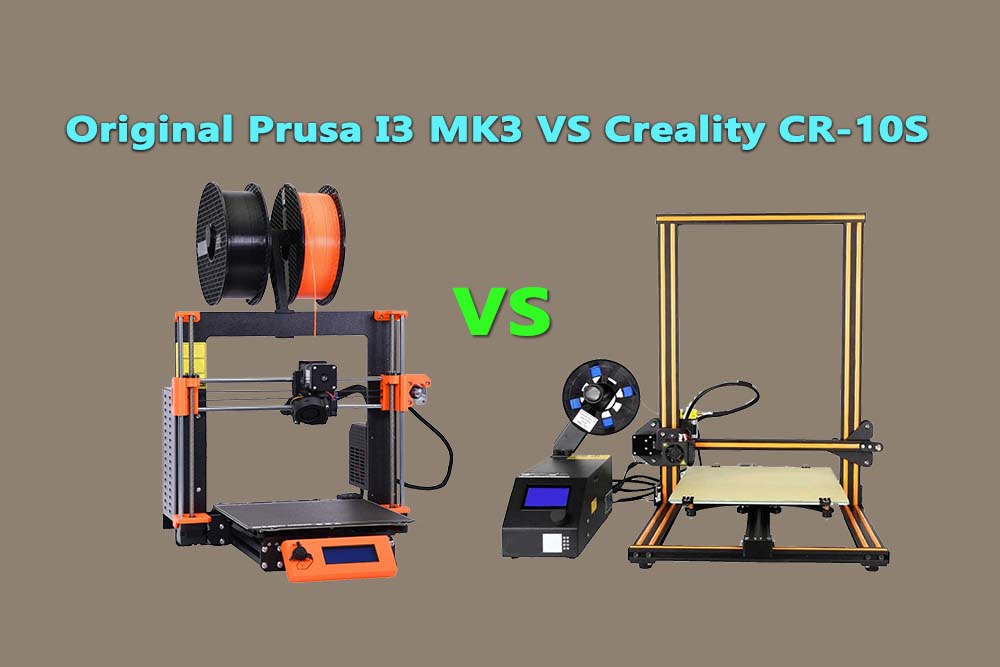

What is Prusa I3 MK3?

The Prusa I3 MK3 is an 3D printer that was designed by Josef Prusa. It is the successor to the popular Prusa I3 MK2S. Some of the new features include a removable build plate, an auto-leveling sensor, and a bowden extruder.

What is Creality CR-10S?

The Creality CR-10S is a 3D printer that was designed by Creality. It is a successor to the popular Creality CR-10. Some of the new features include a removable build plate, an auto-leveling sensor, and a bowden extruder.

COMPARISON

Comparison of motherboard:

The Prusa I3 MK3 has an MKS Gen L motherboard, while the Creality CR-10S has a Megatronics V2.5 motherboard. The MKS Gen L motherboard is a much more advanced motherboard than the Megatronics V2.5 motherboard.

It has a built-in LCD screen, an SD card slot, and a number of connectors for additional components. The Megatronics V2.5 motherboard does not have any of these features.

Comparison of firmware:

The Prusa I3 MK3 uses Marlin firmware, while the Creality CR-10S uses Sailfish firmware. The Marlin firmware is a well-known and well-tested firmware that has been used in a number of 3D printers. The Sailfish firmware is a newer firmware that has not been as widely tested.

Comparison of heated bed:

The Prusa I3 MK3 has an MK42 Heatbed, while the Creality CR-10S has an MK10 Heatbed. The MK42 Heatbed is a more advanced heatbed than the MK10 Heatbed. It has a built-in fan, which helps to keep the build plate warm and prevents warping. The MK10 Heatbed does not have any built-in fans.

Comparison of build volume:

The Prusa I3 MK3 has a build volume of 250x210x200mm, while the Creality CR-10S has a build volume of 300x300x400mm. The Prusa I3 MK3 has a smaller build volume than the Creality CR-10S. The Creality CR-10S has a larger build volume, which allows you to print larger objects.

Comparison of hotend:

The Prusa I3 MK3 uses a J-Head hotend, while the Creality CR-10S uses a E3D V6 hotend. The J-Head hotend is a basic hotend that is not as advanced as the E3D V6 hotend. The E3D V6 hotend is a more advanced hotend that has a number of features, such as an all-metal construction and an optimized cooling.

Comparison of extruder:

The Prusa I3 MK3 uses a bowden extruder, while the Creality CR-10S uses a direct drive extruder. The bowden extruder is a more advanced extruder that has a number of benefits, such as reduced weight and reduced stress on the motors. The direct drive extruder is a less advanced extruder that does not have these benefits.

Comparison of software:

The Prusa I3 MK3 uses Repetier-Host, while the Creality CR-10S uses Cura. Repetier-Host is a well-known and well-tested software that has been used in a number of 3D printers. Cura is a newer software that has not been as widely tested.

Comparison of hardware:

The Prusa I3 MK3 has a 12V 30A power supply, while the Creality CR-10S has a 24V 15A power supply. The Prusa I3 MK3 uses a standard 12V power supply, while the Creality CR-10S uses a more advanced 24V power supply. This allows the Creality CR-10S to run at a higher speed and produce more torque.

Comparison of build plate:

The Prusa I3 MK3 has a PEI build plate, while the Creality CR-10S has a glass build plate. The PEI build plate is a more advanced build plate than the glass build plate. It is less likely to warp and is easier to clean. The glass build plate is a less advanced build plate that is more likely to warp.

Differences:

The Creality CR-10S has a number of features that the Prusa I3 MK3 does not have, such as a removable build plate, an auto-leveling sensor, and a bowden extruder. These features make the Creality CR-10S a more advanced printer than the Prusa I3 MK3.

Similarities:

The two printers have a number of similarities, such as a 12V power supply and a heated bed. These similarities make the two printers easy to compare.

Which printer is better?

The Creality CR-10S is a more advanced printer than the Prusa I3 MK3. It has a number of features that the Prusa I3 MK3 does not have, such as a removable build plate, an auto-leveling sensor, and a bowden extruder. These features make the Creality CR-10S a more advanced printer than the Prusa I3 MK3.

Which printer is better for beginner’s:

The Prusa I3 MK3 is a better printer for beginner’s than the Creality CR-10S. The Prusa I3 MK3 is a more basic printer that is easier to use than the Creality CR-10S. It has a smaller build volume and uses a standard 12V power supply.

The Creality CR-10S is a more advanced printer that is not as easy to use as the Prusa I3 MK3. It has a larger build volume and uses a more advanced 24V power supply.

Which printer is better for experienced users:

The Creality CR-10S is better for experienced users than the Prusa I3 MK3. The Creality CR-10S has a number of features that the Prusa I3 MK3 does not have, such as a removable build plate, an auto-leveling sensor, and a bowden extruder. These features make the Creality CR-10S a more advanced printer than the Prusa I3 MK3.

FAQ’s:

What is build volume of these printers?

The build volume of the Prusa I3 MK3 is 200 x 200 x 180 mm, while the build volume of the Creality CR-10S is 300 x 300 x 400 mm. This makes the Creality CR-10S a more advanced printer with a larger build volume than the Prusa I3 MK3.

What type of extruder does each printer have?

The Prusa I3 MK3 has a bowden extruder, while the Creality CR-10S has a direct drive extruder. The bowden extruder is a more advanced extruder that has a number of benefits, such as reduced weight and reduced stress on the motors. The direct drive extruder is a less advanced extruder that does not have these benefits.

Is the Creality CR-10S easier to use than the Prusa I3 MK3?

The Creality CR-10S is not as easy to use as the Prusa I3 MK3. The Creality CR-10S has a number of features that the Prusa I3 MK3 does not have, such as a removable build plate, an auto-leveling sensor, and a bowden extruder. These features make the Creality CR-10S a more advanced printer than the Prusa I3 MK3.

Q: What is the difference between a bowden extruder and a direct drive extruder?

A: The bowden extruder is a more advanced extruder that has a number of benefits, such as reduced weight and reduced stress on the motors. The direct drive extruder is a less advanced extruder that does not have these benefits.