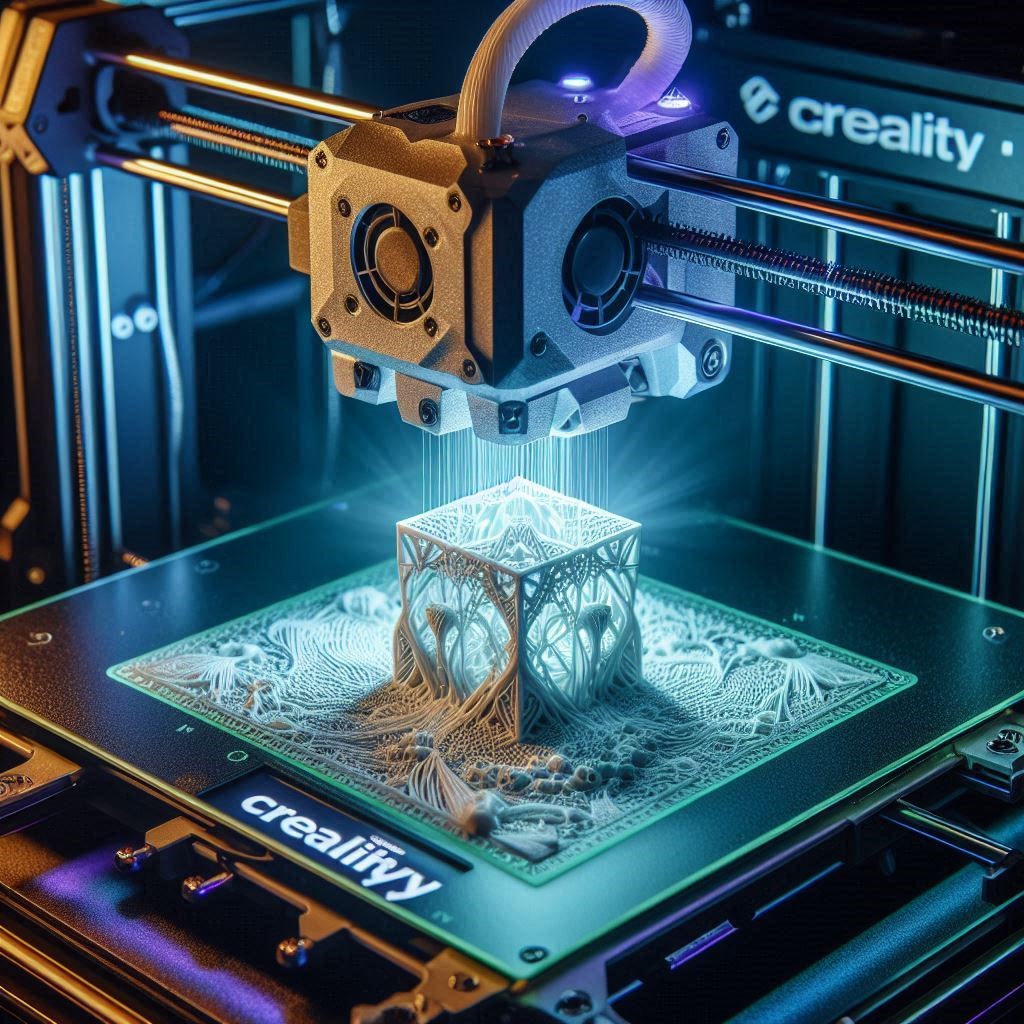

3D printing has transformed the way we conceptualize and create objects, providing unprecedented flexibility and creativity across industries. Among the various types of 3D printing technologies, resin printing has gained immense popularity for its ability to produce highly detailed and intricate models. Creality, a leading name in the 3D printing market, has carved out a significant niche with its range of resin printers and resin models. This blog post delves into Creality 3D printer resin models, examining their features, advantages, applications, and tips for getting the best results.

Understanding Resin 3D Printing

Before we dive into the specifics of Creality’s offerings, it’s essential to grasp the basics of resin 3D printing. Unlike filament-based FDM (Fused Deposition Modeling) printers, which extrude melted plastic to create objects layer by layer, resin printers utilize a liquid photopolymer resin. The printer’s UV light cures this resin, solidifying it in precise patterns to form detailed objects. This method allows for finer details and smoother finishes, making it ideal for applications that require high precision.

The Advantages of Resin Printing

1. High Detail and Precision: Resin printers can achieve resolutions as fine as 10 microns, allowing for intricate details that are often lost in FDM printing.

2. Smoother Surface Finish: The layer lines in resin prints are much less pronounced, resulting in a smoother surface finish right out of the printer.

3. Variety of Materials: Resin comes in various formulations, including flexible, durable, and specialty resins for specific applications.

4. Faster Print Times: In many cases, resin prints can be completed faster than FDM prints, especially for smaller models.

Creality: A Leader in 3D Printing

Creality has established itself as a reliable manufacturer of 3D printers, catering to both hobbyists and professionals. Their range includes FDM printers, but they have made significant strides in the resin printing market with models like the Creality LD-002R, LD-006, and the new HALOT series. Each model is designed to deliver high performance, usability, and quality.

Overview of Creality Resin Printers

1. Creality LD-002R: This entry-level resin printer is perfect for beginners. It features a build volume of 120 x 68 x 170 mm and a monochrome LCD screen that allows for faster curing times and longer lifespan.

2. Creality LD-006: This mid-range printer offers a larger build volume (218 x 123 x 235 mm) and advanced features like a touchscreen interface, dual linear rails for improved stability, and a high-resolution LCD screen for precise printing.

3. Creality HALOT Series: The HALOT printers represent Creality’s latest advancements, featuring high-speed printing, large build volumes, and improved cooling systems. These models utilize cutting-edge technology, making them suitable for professional use.

Creality 3D Printer Resin Models: What to Expect

Creality’s resin printers are capable of producing a wide variety of models, ranging from detailed miniatures to functional prototypes. Some popular applications include:

1. Miniatures and Figurines

One of the most popular uses of resin printers is the creation of highly detailed miniatures for tabletop games, dioramas, and collectibles. Creality printers excel in this area, allowing hobbyists to create lifelike characters and environments with intricate designs.

2. Prototyping

For designers and engineers, the ability to quickly prototype ideas is invaluable. Creality’s resin printers can produce functional prototypes that can be tested for form, fit, and function. The precision and detail of resin prints make them ideal for assessing product designs before moving to mass production.

3. Jewelry Making

Jewelry designers benefit greatly from the capabilities of resin printing. The fine detail achievable with Creality printers allows for the creation of complex designs that can be directly cast into metal, streamlining the design-to-production process.

4. Dental and Medical Applications

In the medical field, resin printing is used to create dental molds, surgical guides, and anatomical models. The accuracy and surface finish provided by Creality printers make them suitable for such critical applications.

5. Custom Parts and Accessories

Whether it’s replacement parts for machinery or custom accessories, the versatility of resin printing allows users to create tailored solutions that meet their specific needs.

Tips for Creating High-Quality Resin Prints with Creality

To achieve the best results from your Creality resin printer, consider the following tips:

1. Proper Bed Leveling

Ensure that the build plate is correctly leveled before starting a print. This is crucial for adhesion and the overall success of the print.

2. Use High-Quality Resin

Invest in high-quality resin that is compatible with your specific printer model. Cheaper resins may lead to poor print quality or complications during the printing process.

3. Optimize Print Settings

Adjust print settings like exposure time, layer height, and lift speed based on the resin you are using and the specific model you are printing. Refer to the resin manufacturer’s guidelines for best practices.

4. Post-Processing

After printing, thorough post-processing is essential. This includes washing the printed model in isopropyl alcohol (IPA) to remove excess resin and curing the model under UV light for optimal strength.

5. Ventilation and Safety

Always work in a well-ventilated area and wear appropriate safety gear, such as gloves and goggles, when handling resin. This will help protect you from potential hazards associated with resin printing.

Conclusion

Creality’s range of resin 3D printers offers remarkable capabilities for anyone interested in 3D printing, from hobbyists to professionals. The high level of detail, smooth finishes, and diverse applications make resin printing an exciting avenue for creativity and innovation. Whether you’re creating intricate miniatures, prototyping designs, or crafting custom jewelry, Creality’s printers can help bring your visions to life.

As the world of 3D printing continues to evolve, Creality remains at the forefront, providing reliable technology and a commitment to quality. With the right techniques and knowledge, you can harness the power of resin printing to unlock a world of possibilities.