What is filament?

Filament is the material that 3D printers use to create objects. Filament is a type of plastic that is melted and extruded through a nozzle to produce the desired shape. There are many types of filament available, each with different characteristics. Some filaments are more flexible than others, while others are more durable or have a higher melting point.

What is sensor?

A sensor is a device that detects or measures a physical quantity and converts it into a signal which can be read by an observer or by an instrument. Sensors are used in many industries, such as manufacturing, automotive, aerospace, and defense.

They are also used in consumer products, such as cell phones, digital cameras, and thermostats. Sensors come in many different types and sizes. Some are small enough to fit on a circuit board while others are large enough to fill a room.

What is a filament sensor?

A filament sensor is a device that monitors the amount of filament remaining in a 3D printer’s supply reel. When the sensor detects that there is no more filament left, it will automatically stop the printer from printing.

This prevents the printer from running out of filament in the middle of a print job and causing damage to the extruder or other printer components.

How does the filament sensor work?

The filament sensor is placed on the spool of filament and monitors the amount of filament being used. The sensor will send a signal to the printer when the filament is running low, indicating that more filament needs to be loaded.

The sensor can also be used to pause the print job if the filament runs out completely, preventing the print from being ruined.

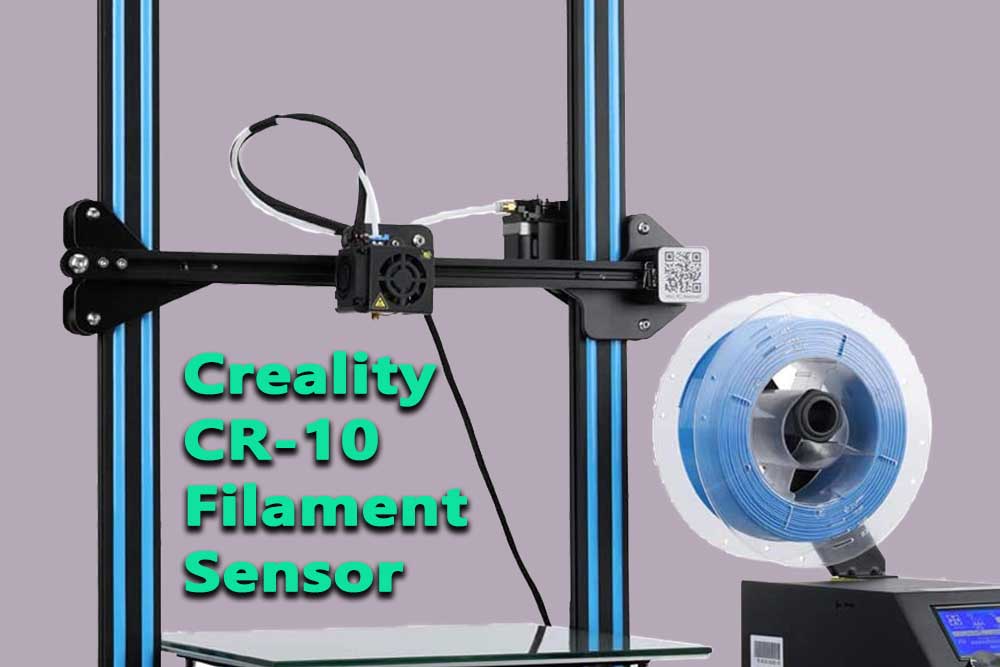

Role of filament sensor in crealtiy CR-10:

The creality CR-10 filament sensor plays an important role in ensuring that the 3D printer is always using the correct amount of filament. When the sensor detects that the filament is running low, it will send a signal to the printer to stop printing.

This prevents the printer from running out of filament in the middle of a print job and causing damage to the extruder or other printer components.

Types of filament sensor:

There are two main types of filament sensor: optical and mechanical.

Optical Sensor:

Optical sensors use a light source and a photosensitive element to detect the presence or absence of filament. These sensors are typically more accurate than mechanical sensors, but they can be more expensive.

Mechanical sensor:

Mechanical sensors use a physical switch to detect the presence or absence of filament. These sensors are less expensive than optical sensors, but they can be less accurate.

Filament sensors can also be classified by their mounting location. Some filament sensors are mounted on the spool of filament, while others are mounted on the extruder itself.

Advantages of using creality CR-10 with filament sensor:

The main advantage of using a creality CR-10 with a filament sensor is that it ensures that the 3D printer is always using the correct amount of filament. This prevents the printer from running out of filament in the middle of a print job and causing damage to the extruder or other printer components.

Additionally, the creality CR-10 filament sensor can be used to pause the print job if the filament runs out completely, preventing the print from being ruined.

Disadvantage of using creality CR-10 with filament sensor:

One disadvantage of using a creality CR-10 with a filament sensor is that it can be more expensive than a 3D printer without a sensor. Additionally, the accuracy of the sensor can vary, and some sensors may not be able to accurately detect the amount of filament remaining in the spool.

Which filament sensor is best for CR-10?

There is no definitive answer to this question, as the best filament sensor for CR-10 will depend on your specific needs and budget. However, we would recommend considering an optical sensor, as these are typically more accurate than mechanical sensors.

Additionally, you may want to consider a filament sensor that is mounted on the extruder itself, as this can make it easier to install and use.

If filament sensor does not working properly?

If your filament sensor is not working properly, there are a few things you can try to troubleshoot the issue. First, check to make sure that the sensor is properly calibrated. If the sensor is not properly calibrated, it may not be able to accurately detect the amount of filament remaining in the spool.

Additionally, you can try cleaning the sensor using compressed air or a small brush. If the sensor is still not working properly, you may need to replace it with a new one.

There are two main types of filament sensor: optical and mechanical. Optical sensors are typically more accurate than mechanical sensors, but they can be more expensive. Mounting location is another factor to consider when choosing a filament sensor.

Some sensors are mounted on the spool of filament, while others are mounted on the extruder itself. Ultimately, the best type of sensor for your needs will depend on your specific budget and requirements.

FAQ’s:

Q: What is the difference between an optical and a mechanical filament sensor?

A: Optical sensors use a light source and a photosensitive element to detect the presence or absence of filament. Mechanical sensors use a physical switch to detect the presence or absence of filament.

Q: Which type of filament sensor is best for my CR-10?

A: There is no definitive answer to this question, as the best filament sensor for CR-10 will depend on your specific needs and budget. However, we would recommend considering an optical sensor, as these are typically more accurate than mechanical sensors.

Additionally, you may want to consider a filament sensor that is mounted on the extruder itself, as this can make it easier to install and use.

Q: If my filament sensor is not working properly, what can I do?

A: There are a few things you can try to troubleshoot the issue. First, check to make sure that the sensor is properly calibrated. If the sensor is not properly calibrated, it may not be able to accurately detect the amount of filament remaining in the spool.

Additionally, you can try cleaning the sensor using compressed air or a small brush. If the sensor is still not working properly, you may need to replace it with a new one.