What is Extruder?

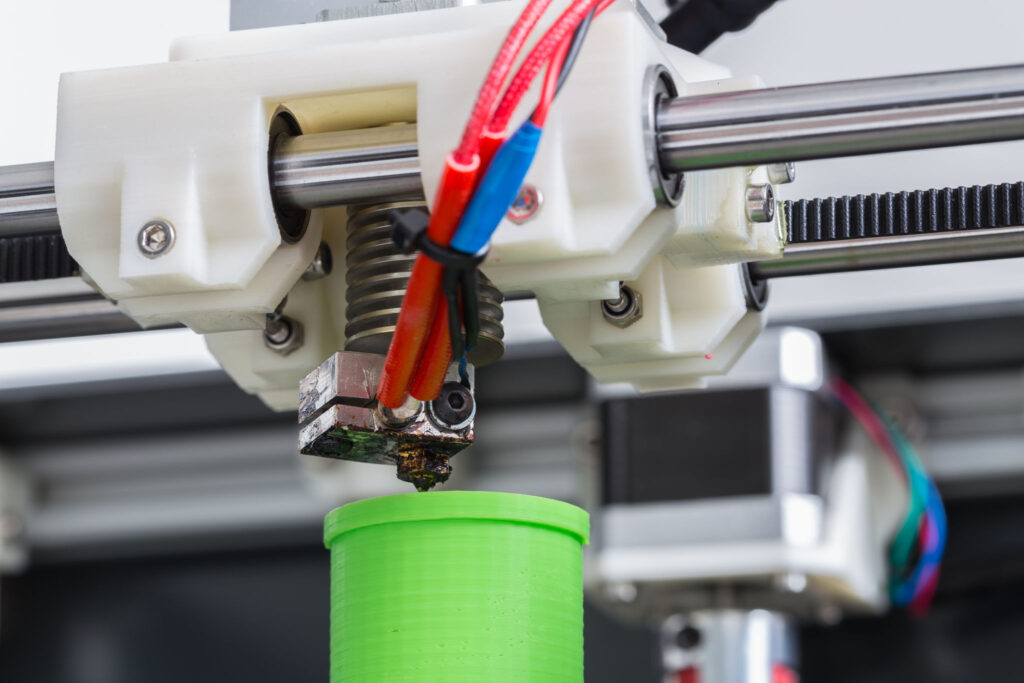

An extruder is a device used to melt and push filament through a hot end. The molten filament is forced out of the nozzle, where it immediately hardens into a solid object. Extruders come in various shapes and sizes, but all share the same basic functionality.

What is role of extruder?

The extruder is responsible for melting the filament and pushing it through the hot end. The molten filament is then forced out of the nozzle, where it immediately hardens into a solid object.

What is role of extruder in CR 10?

The extruder is responsible for melting the filament and pushing it through the hotend. The molten filament is then forced out of the nozzle, where it immediately hardens into a solid object. The extruder on the CR 10 is a bit different than most, as it uses a Bowden setup.

This means that the motor that drives the filament is located in the printer’s chassis, and the hotend is attached to a tube that runs down to the extruder. This setup allows for better prints, as it reduces weight on the Hotend. However, it can be a bit more difficult to troubleshoot if something goes wrong.

How it works?

When the printer starts up, the filament is loaded into the extruder. The motor drives the filament through the hotend and into the print bed. The molten filament is then forced out of the nozzle, where it immediately hardens into a solid object.

What to do if extruder not working?

If the extruder isn’t working, there are a few things you can do to try and fix it. First, make sure that the filament is properly loaded into the extruder. Then, check the temperature of the hotend. If it’s too low, increase it until the filament starts to melt. You can also try cleaning the nozzle with a wire brush. If none of these solutions work, you may need to replace the extruder.

What are common problems with extruders?

If your CR 10 extruder is not working, there are a few things that you can check. First, make sure that the filament is properly loaded into the extruder. If the filament is not feeding properly, it will not be able to melt and push through the hotend.

Next, check the tension on the drive gear. If the tension is too loose, the filament will not be pushed properly and can slip. Finally, make sure that the hotend is properly heated. If the hotend is not hot enough, the filament will not melt properly.

If you are still having problems with your extruder, it is best to contact a qualified technician for assistance. Trying to fix an extruder on your own can be difficult, and can often result in further damage.

Types of extruders:

There are many different types of extruders available on the market. Here are a few of the most common types:

– Single Extruder: This type of extruder uses a single filament to produce prints. It is the most common type of extruder and is used in most 3D printers.

– Dual Extruder: This type of extruder uses two filaments to produce prints. This allows for faster printing speeds and more complex designs.

– Bowden Extruder: This type of extruder is used in high-resolution printers. It uses a tube to move the filament from the motor to the hotend, which reduces weight on the hotend and allows for faster printing speeds.

– Direct Drive Extruder: This type of extruder mounts the motor directly on the hotend. This results in better prints, but can be more difficult to troubleshoot if something goes wrong.

No matter what type of extruder you have, it is important to keep it clean and free of debris.

Which extruder is best for CR 10?

The best extruder for the CR 10 is the Bowden Extruder. This type of extruder uses a tube to move the filament from the motor to the hotend, which reduces weight on the hotend and allows for faster printing speeds.

In CR 10 which extruder is used?

The CR 10 uses a Bowden Extruder. This type of extruder uses a tube to move the filament from the motor to the hotend, which reduces weight on the hotend and allows for faster printing speeds.

Conclusion:

After doing some research, it seems that the issue may be with the extruder itself. Some users have found that the problem is resolved by cleaning out the nozzle, while others have had to replace the extruder altogether. Hopefully, this guide has been helpful in diagnosing and resolving the creality CR-10 extruder not working issue.

FAQ’s:

What should I do if my Creality CR-10 extruder isn’t working?

Why isn’t my Creality CR-10 extruder working?

How can I fix my Creality CR-10 extruder if it’s not working?

If your Creality CR-10 extruder isn’t working, it could be due to a few different reasons. First, make sure that your filament is properly loaded and that there isn’t anything blocking the path of the filament. If the filament is properly loaded and there doesn’t seem to be anything blocking it, then it’s possible that the extruder motor itself is defective.

To check this, you can try manually rotating the filament using your fingers. If it’s not possible to rotate the filament, then the motor is likely defective. If you’ve determined that the extruder motor is defective, then you’ll need to replace it in order to get your Creality CR-10 extruder working again.

Question: Why is my extruder not working?

Answer: There are a few possible reasons why your extruder may not be working. First, check to make sure that there is filament loaded into the filament chamber. If there is filament loaded, then check to see if the filament is jammed in the nozzle. If the filament is not jammed, then the problem may be with the heating element or the thermistor.

Question: How do I fix a jammed extruder?

Answer: If your extruder is jammed, the first thing you will want to do is remove the filament from the filament chamber. Once the filament is removed, you will want to clean out the nozzle using a paper clip or a toothpick. If the filament is still jammed, then you may need to use a needle or a screwdriver to remove it.

Question: How do I fix a broken heating element?

Answer: If your heating element is broken, you will need to replace it. You can purchase a new heating element from your local hardware store or from an online retailer.

Question: How do I fix a broken thermistor?

Answer: If your thermistor is broken, you will need to replace it. You can purchase a new thermistor from your local hardware store or from an online retailer.