The Creality CR-10 is a great 3D printer that has been getting a lot of attention lately. One of the things that makes this printer so great is its bed adhesion. The bed adhesion on the CR-10 is amazing, and it keeps your prints from coming off the bed during printing. This is a huge plus, especially for novice users who may not have as much experience with 3D printing.

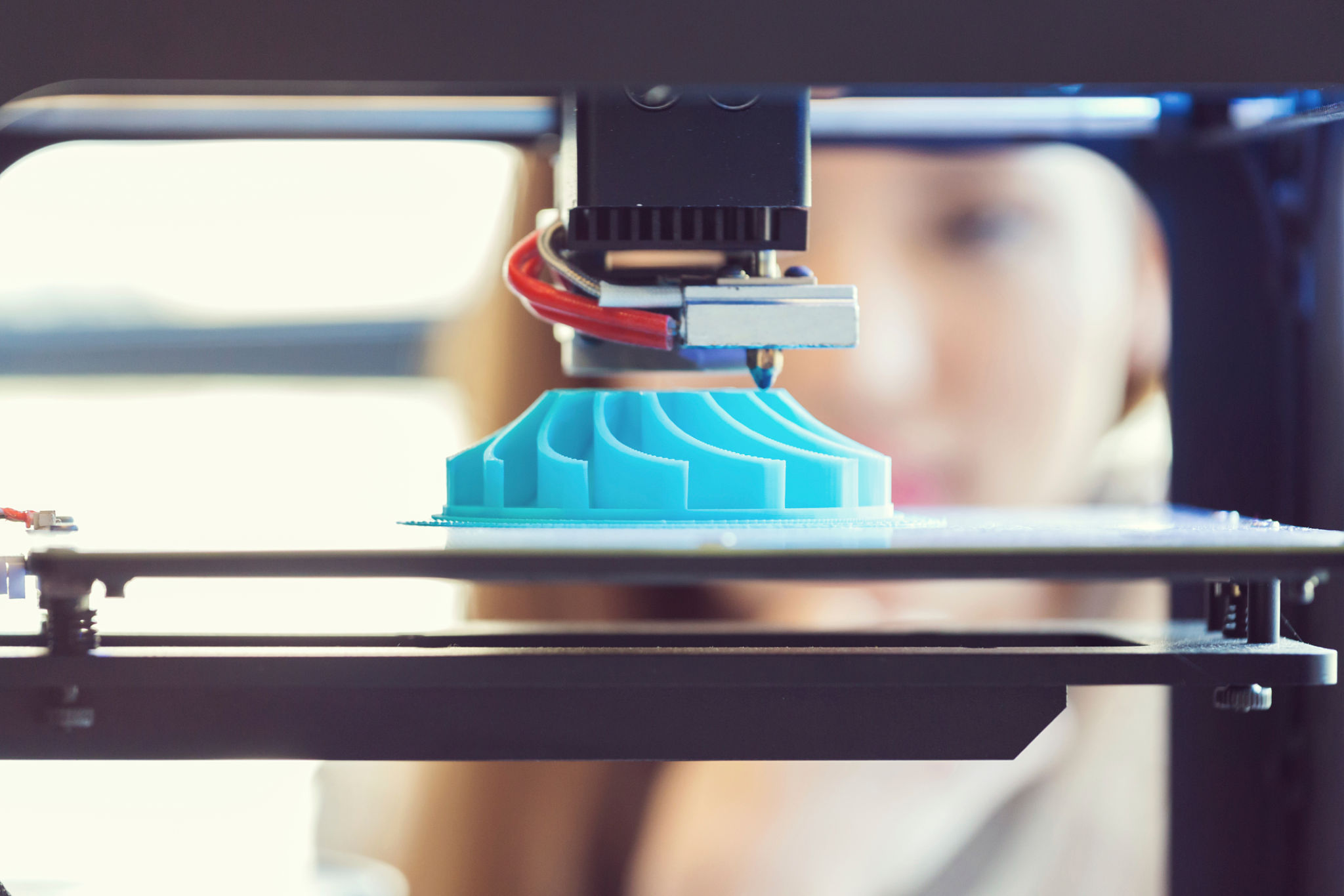

What is 3D printing?

3D printing is the process of creating three-dimensional objects from a digital file. This is done by using a printer that prints successive layers of material until the object is completed.

3D printing has become increasingly popular in recent years, and it continues to grow in popularity. There are many different types of 3D printers available, each with its own advantages and disadvantages.

What is bed adhesion?

Bed adhesion is the process of bonding a material to a substrate. This is usually done by using an adhesive or a mechanical means. Bed adhesion is important for 3D printing, as it ensures that your prints stay on the bed during printing.

Without good bed adhesion, your prints may come off the bed and be ruined. The creality CR-10 has amazing bed adhesion, and it keeps your prints from coming off the bed during printing.

This is a huge plus, especially for novice users who may not have as much experience with 3D printing. If you are looking for a great 3D printer that has amazing bed adhesion, then the creality CR-10 is the printer for you.

Creality CR 10 bed adhesion:

How bed adhesion produced?

There are a few factors that can influence bed adhesion. The main factor is the type of filament you are using. For example, if you are using a high-temperature filament like ABS or PLA, then you will need to use a heated bed to keep the filament warm and help it stick to the print bed.

If you are using a lower-temperature filament like PETG, you may not need to use a heated bed. Another factor that can affect bed adhesion is the surface of your print bed.

If the surface is too smooth, then the filament may not stick to it. You can increase bed adhesion by adding some texture to the surface of your print bed. You can do this by adding some sandpaper to the surface, or by using a bed adhesion spray like hairspray or Elmer’s Glue.

How to improve it?

There are a few things you can do to improve the bed adhesion on your Creality CR-10 3D printer:

1. Increase the temperature of the build plate. This will help the filament stick better.

2. Try using a different adhesive or tape to improve the grip between the build plate and the filament.

3. Make sure that the build plate is clean and free of dirt and dust.

4. Use a higher print speed to help the filament stick better.

Which things is used to prevent bed adhesion?

There are a few things you can use to help prevent bed adhesion on your 3D printer:

1. Heated build plate – this will help to keep the filament warm and help it stick better to the print bed.

2. Bed adhesion spray – hairspray or Elmer’s Glue can be sprayed onto the surface of the print bed to help improve grip.

3. GlassBuild Plate – if you are having trouble with bed adhesion, you can try using a glass build plate instead of the standard build plate that comes with the printer. This will give you a smooth, flat surface to print on.

4. PEI Sheet – another option for improving bed adhesion is to use a PEI sheet on the print bed. PEI is a plastic material that has a very smooth surface, and it will help the filament stick to the print bed better.

5. BuildTak – if you are having trouble with bed adhesion, you can try using a buildtak sheet on the print bed. BuildTak is a special adhesive sheet that helps to improve bed adhesion. It can be difficult to remove after printing, so make sure you plan accordingly.

In these cases, using a raft or sucker stick can help to improve the print quality. Overall, the Creality CR-10 is a great 3D printer that can produce high quality prints if the bed adhesion issues are dealt with.

FAQ’s:

Why doesn’t my print stick to the bed?

There are a few reasons why your print might not stick to the bed. One reason is that the surface of the bed may not be level, which can cause prints to curl or warp. Another reason is that the bed may not be clean, which can cause prints to come off the bed during printing. Make sure to keep the bed clean and level for best results.

What can I do to improve bed adhesion?

There are a few things you can do to improve bed adhesion. One thing you can do is apply a coat of glue or hairspray to the surface of the bed. You can also try using a brim on your print to help it stick to the bed.

My print keeps coming off the bed. What can I do?

If your print keeps coming off the bed, there are a few things you can try. One thing you can do is make sure that the surface of the bed is clean and level. You can also try using a brim on your print to help it stick to the bed. If none of these solutions work, you may need to upgrade your printer’s bed adhesion system.