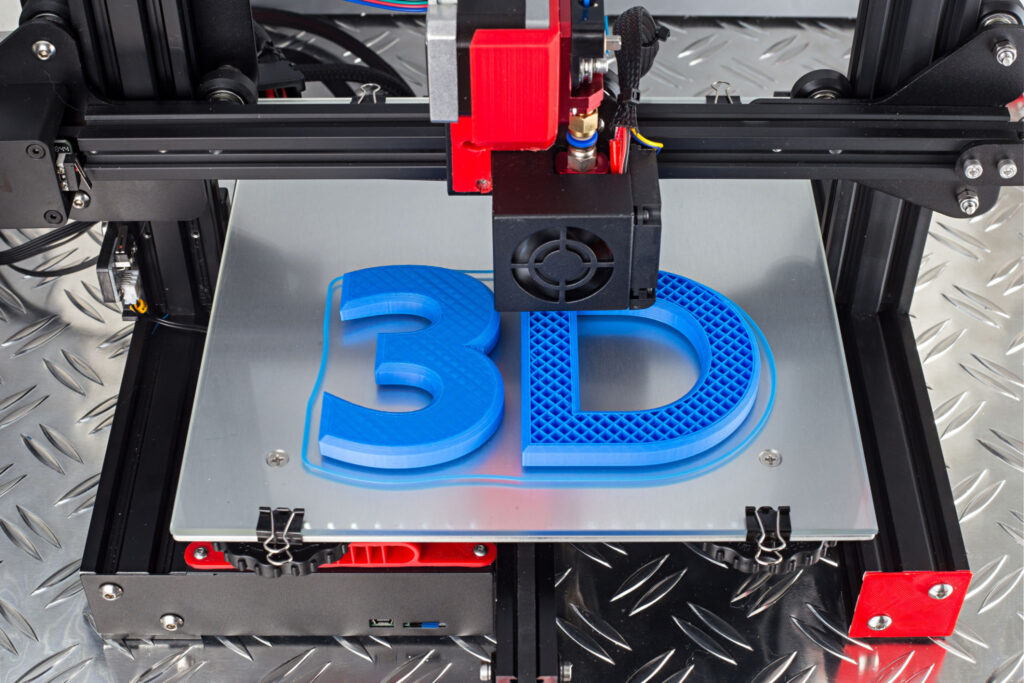

What is build plate?

A build plate is a flat surface, usually made of metal or plastic, on which a 3D printer prints a three-dimensional object. The build plate is the part of the 3D printer where the print material is deposited.

The build plate is heated to ensure that the print material adheres to it and does not cool and fall off during the printing process. Most 3D printers have one build plate, but some high-end printers have two or more build plates to allow multiple objects to be printed at the same time.

Creality CR-10s pro build plate

The Creality CR 10S Pro is a 3D printer that comes with a heated build plate. The build plate is made of aluminum and is coated with a layer of BuildTak, which is a material that helps the print material to stick to the build plate and makes it easier to remove the printed object.

The build plate can be heated up to 100°C (212°F), which helps to prevent warping of the printed object. The CR 10S Pro also has an enclosed printing area, which helps to protect the printed object from drafts and dust.

What are some of the benefits of using a heated build plate?

There are several benefits of using a heated build plate:

- It prevents warping of the printed object.

- It helps the print material to stick to the build plate.

- It makes it easier to remove the printed object from the build plate.

- It protects the printed object from drafts and dust.

Types of build plate used in cr 10s pro:

There are several types of build plate that can be used in the Creality CR 10S Pro:

- Aluminum build plate.

- BuildTak build plate.

- Glass build plate.

- PEI (polyetherimide) build plate.

- PCB (printed circuit board) build plate.

Which type of build plate is best for printing ABS?

The best type of build plate for printing ABS is a PEI (polyetherimide) build plate, because it has a smooth surface that helps the print material to stick to the build plate. The aluminum and BuildTak build plates are also good choices for printing ABS, but they may not be as smooth as the PEI build plate and may cause the print material to stick a little bit more.

The glass build plate should not be used for printing ABS, because the print material may stick to the build plate and be difficult to remove. The PCB (printed circuit board) build plate should not be used for printing ABS, because it is not smooth and may cause the print material to stick.

What are some of the benefits of using a glass build plate?

There are several benefits of using a glass build plate:

- It is easy to clean and does not require any special cleaning supplies.

- It is durable and can withstand a lot of wear and tear.

- It is lightweight and easy to move around.

- It has a smooth surface that helps the print material to stick to the build plate.

- It is resistant to heat and can be heated up to 250°C (482°F).

Which type of build plate is best for printing PLA?

The best type of build plate for printing PLA is a PEI (polyetherimide) build plate, because it has a smooth surface that helps the print material to stick to the build plate. The aluminum and BuildTak build plates are also good choices for printing PLA, but they may not be as smooth as the PEI build plate and may cause the print material to stick a little bit more.

The glass build plate should not be used for printing PLA, because the print material may stick to the build plate and be difficult to remove. The PCB (printed circuit board) build plate should not be used for printing PLA, because it is not smooth and may cause the print material to stick.

How do I clean my cr 10s pro build plate?

The best way to clean your cr 10s pro build plate is to use a soft cloth or brush and warm water. You can also use a mild soap if the build plate is very dirty. Avoid using harsh cleaning chemicals, as they may damage the build plate.

If the build plate is extremely dirty, you can try soaking it in warm water with a mild soap for a few minutes before scrubbing it with a soft cloth or brush.

The best type of build plate for printing PLA is also a PEI (polyetherimide) build plate, because it has a smooth surface that helps the print material to stick to the build plate. You can clean your cr 10s pro build plate with a soft cloth or brush and warm water.

If the build is very dirty, you can try soaking it in warm water with a mild soap for a few minutes before scrubbing it with a soft cloth or brush.

FAQ’s:

How do I choose the right type of build plate for my 3D printer?

The best way to choose the right type of build plate for your 3D printer is to think about the type of material you will be printing with. If you are going to be printing with ABS, then you will want a PEI (polyetherimide) build plate.

If you are going to be printing with PLA, then you will also want a PEI (polyetherimide) build plate. If you are unsure about which type of build plate to choose, you can always contact the manufacturer of your 3D printer for more information.

What is the best way to clean my cr 10s pro plate?

The best way to clean your cr 10s pro build plate is to use a soft cloth or brush and warm water. You can also use a mild soap if the build plate is very dirty. Avoid using harsh cleaning chemicals, as they may damage the build plate.

If the build plate is extremely dirty, you can try soaking it in warm water with a mild soap for a few minutes before scrubbing it with a soft cloth or brush.

What are the types of build plate?

There are three types of build plate: the aluminum build plate, the BuildTak build plate, and the PEI (polyetherimide) build plate. The aluminum build plate is a good choice for printing ABS because it is durable and can withstand a lot of wear and tear.

The BuildTak build plate is a good choice for printing PLA because it has a smooth surface that helps the print material to stick to the build plate. The PEI (polyetherimide) build plate is the best choice for printing PLA because it has a smooth surface that helps the print material to stick to the build plate.