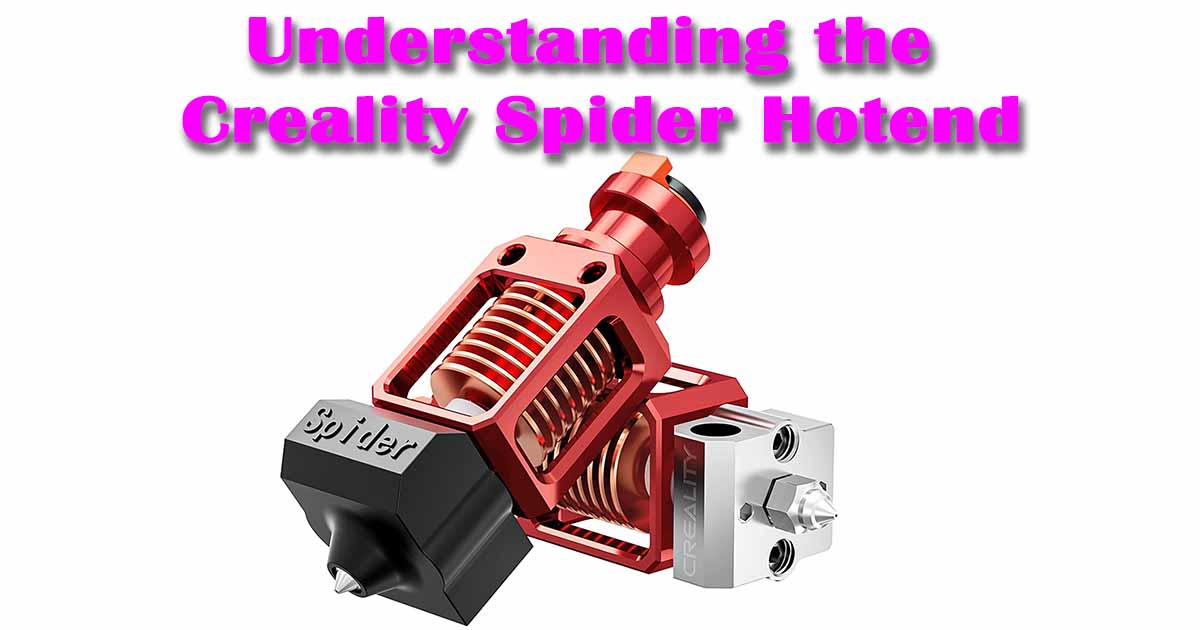

In the ever-evolving world of 3D printing, Creality has been a pioneering force, continually pushing the boundaries of what’s possible. Their latest innovation, the Creality Spider Hotend, is creating quite a buzz among enthusiasts and professionals alike.

With its cutting-edge technology and impressive features, the Spider Hotend promises to revolutionize the 3D printing experience.

Creality has long been recognized for its commitment to delivering high-quality 3D printers, and the Spider Hotend is no exception. This innovative component takes center stage in Creality’s quest for precision, speed, and reliability in 3D printing.

Whether you’re a seasoned maker or just dipping your toes into the world of 3D printing, the Creality Spider Hotend is set to make your printing projects more efficient and exciting than ever before.

But what sets the Spider Hotend apart from its predecessors and competitors? How does it enhance the 3D printing process, and what can users expect from this remarkable piece of technology?

In this article, we will delve deep into the world of Creality’s Spider Hotend, exploring its features, benefits, and the incredible possibilities it brings to the realm of 3D printing. Join us on this journey of discovery as we unravel the web of innovation spun by Creality’s Spider Hotend.

What is a Hotend

A pivotal element in the realm of 3D printing, a hotend serves as the essential melting point where the printer filament undergoes heating and subsequent extrusion to meticulously craft 3D models layer by layer. Much akin to the precision of a nib on a pen, it steers the molten filament onto the build platform. If you’re interested in exploring a comprehensive list of Creality 3D printers, be sure to check out our curated collection of Creality 3D Printers on Creality 3D Printers List for an in-depth look into top-quality 3D printing solutions.

The design and efficiency of a hotend play a significant role in the print quality, speed, and the range of materials a printer can handle.

In relation to the “Creality Spider Hotend”, it is a specific hotend model designed by Creality, renowned for its durability, high-temperature resilience, and adaptability, making it a popular choice among 3D printing enthusiasts and professionals alike.

The Birth of the Creality Spider Hotend

In the evolving landscape of 3D printing, the birth of the Creality Spider Hotend marks a significant leap forward. Born out of a relentless commitment to innovation, this hotend is designed to address many of the common challenges faced by 3D printing enthusiasts.

Boasting improved heat dissipation, reduced clogging, and an enhanced filament feeding system, the Spider Hotend is the epitome of precision and reliability. Creality, already a respected name in the 3D printing world, further cements its reputation for pushing boundaries and setting new standards.

With the introduction of the Spider Hotend, the future of seamless and efficient 3D printing appears even brighter, promising makers and hobbyists alike a transformative experience.

Key Features of the Creality Spider Hotend

The Creality Spider Hotend stands out as an innovative component in the 3D printing realm. Among its key features is its superior thermal performance, ensuring consistent and optimal heating during the printing process. This is largely attributed to its efficient heat break and heat sink design.

The Spider Hotend also boasts of a user-friendly nozzle replacement system, allowing for quick and hassle-free changes, streamlining the printing workflow. Its durable build quality, paired with excellent thermal insulation, minimizes the risks of clogging or filament jams.

Moreover, its compatibility with a range of filament types highlights its versatility. As a product under the reputable Creality brand, users can expect a combination of reliability, efficiency, and precision from the Spider Hotend.

Material Compatibility

The Creality Spider Hotend, a popular component in 3D printing circles, has renewed discussions around the concept of material compatibility. Given the hotend’s function – to heat and extrude filament – it’s paramount that it is compatible with a diverse range of materials, from standard PLA and ABS to more exotic composites.

Incompatibility can lead to filament jams, uneven extrusion, or even damage to the hotend. With the rapid evolution of filament types and the demand for superior print quality, the compatibility of a hotend with various materials becomes a decisive factor for enthusiasts and professionals alike.

The Creality Spider Hotend, by ensuring broad material compatibility, cements its position as a reliable choice in the 3D printing world.

Enhanced Heat Dissipation

The Creality Spider Hotend, a pivotal component in 3D printing, showcases advancements in heat dissipation techniques, ensuring optimal performance during extended printing sessions. A primary concern with hotends is the potential for overheating, which can compromise print quality and even damage the printer.

With the Spider Hotend, Creality has introduced superior heat sinks and enhanced cooling designs that rapidly disperse heat away from the filament path. This not only guarantees a consistent temperature during extrusion but also elongates the lifespan of the equipment.

As 3D printing technology evolves, innovations like the Spider Hotend underline the importance of efficient heat management in producing high-quality prints.

Easy Installation and Maintenance

In the realm of 3D printing, the Creality Spider Hotend stands out not only for its impressive performance but also for its user-friendly design tailored for hassle-free installation and maintenance. Creality ensures that even beginners can swiftly set up the Spider Hotend with straightforward instructions and intuitive components.

Moreover, the design addresses common maintenance issues experienced in other hotends. The modular nature of the Spider allows for quick disassembly, making it easier to clean or replace parts when needed.

This combination of easy installation and low-maintenance demands makes the Creality Spider Hotend an attractive choice for both novices and seasoned 3D printing enthusiasts.

Nozzle Variety and Customizability

The Creality Spider Hotend stands out not only for its robust performance but also for the vast array of nozzle varieties it offers. Users can select from an assortment of nozzle diameters and materials, allowing for fine-tuning in layer resolution and compatibility with various filament types.

The hotend design ensures quick and hassle-free nozzle changes, promoting adaptability for diverse printing requirements. Furthermore, the Spider Hotend’s customizability extends beyond just the nozzle: its modular setup is built for upgrades and adaptability, keeping in line with Creality’s commitment to iterative improvement.

This combination of variety and customizability ensures that users can tailor their printing experience to their precise needs, boosting both efficiency and creativity.

Improved Print Quality

The advent of the Creality Spider Hotend has ushered in a new era for 3D printing aficionados, promising unprecedented improvements in print quality. This state-of-the-art hotend, tailored for precision, boasts streamlined filament feeding and enhanced thermal stability.

The meticulous design minimizes common printing issues like stringing and blobbing, resulting in smoother, more consistent layers. The Creality Spider Hotend also significantly reduces clogging and filament wastage, thanks to its optimized heat distribution.

Its integration into 3D printers not only refines print details but also elevates the overall reliability of printing tasks. For hobbyists and professionals alike, the Spider Hotend is a game-changer, propelling the standards of 3D printed objects to new heights.

Comparing Creality Spider Hotend to Other Hotends

The Creality Spider Hotend, recently introduced to the 3D printing community, has garnered attention for its unique features and performance capabilities.

When compared to other popular hotends in the market, the Spider stands out for its efficient heat dissipation, which contributes to more consistent filament melting and improved print quality. Its robust design ensures minimal clogging and smoother filament flow.

In contrast, other hotends like the E3D V6 and the Mosquito, while commendable for their track record, exhibit different heat break and nozzle designs, which can affect the print consistency and maintenance frequency.

However, each hotend has its merits and caters to specific user needs. The Creality Spider, though a newcomer, is quickly establishing its place as a formidable contender in the hotend market.

Longevity and Durability

When discussing 3D printing components, the Creality Spider Hotend stands out as a benchmark for longevity and durability. As the heart of the 3D printing process, the hotend’s resilience can significantly impact the consistency and quality of prints.

The Creality Spider Hotend is designed with high-grade materials and precision engineering to withstand prolonged usage and high temperatures without compromising performance. This results in fewer replacements and reduced maintenance, saving both time and resources for 3D printing enthusiasts.

The consistent thermal properties and robust construction of the Spider Hotend ensure that it remains a dependable component in the 3D printing ecosystem, embodying the essence of longevity and durability.

Price Point and Value for Money

In the 3D printing community, value for money is of paramount importance when investing in printer components. The Creality Spider Hotend, for instance, has been a topic of discussion in this context.

Its price point is strategically positioned to appeal to both hobbyists and professionals, offering a balance between affordability and performance. This component’s design is lauded for its efficient heat dissipation and consistent extrusion, ensuring high-quality prints.

Furthermore, its compatibility with a variety of filament types amplifies its value proposition. When analyzing the cost against the benefits, the Creality Spider Hotend emerges as a testament to obtaining genuine value for money in the realm of 3D printing.

User Testimonials

Over recent months, the Creality Spider Hotend has gained considerable attention among 3D printing enthusiasts. User testimonials consistently highlight its robust performance, efficient heat distribution, and ease of installation.

Many users have praised its ability to maintain stable temperatures, which in turn ensures high-quality, consistent prints. Additionally, the Spider Hotend stands out for its compatibility with a diverse range of filaments, a feature that has been commended by several 3D printing veterans.

A common sentiment echoed among users is the noticeable enhancement in print quality after switching to this hotend. Overall, the positive feedback and user testimonials underscore the Creality Spider Hotend’s effectiveness and reliability in the world of 3D printing.

Conclusion

The Creality Spider Hotend has emerged as a game-changing innovation in the realm of 3D printing. Its exceptional features and capabilities have solidified its position as a must-have component for both seasoned 3D printing enthusiasts and newcomers to the craft.

As we’ve explored in this article, the Spider Hotend offers a myriad of benefits that significantly enhance the 3D printing experience.

First and foremost, precision is at the core of the Spider Hotend’s design. Its ability to maintain consistent temperatures and deliver precise filament flow ensures that your 3D prints come out with impeccable detail and accuracy. Whether you’re crafting intricate prototypes or functional parts, the Spider Hotend’s reliability is truly a game-changer.

Moreover, the Spider Hotend’s versatility is worth celebrating. It seamlessly handles a wide range of filaments, opening up a world of creative possibilities. From standard PLA to exotic materials like flexible TPU and abrasive carbon fiber, this hotend can tackle them all with ease.

Efficiency is another standout feature of the Spider Hotend, thanks to its rapid heating and cooling capabilities. Say goodbye to long waiting times and hello to faster project completion.