What Is It and What Are the Advantages?

When it comes to 3D printing, the extruder is one of the most important parts of the process. This is because it is responsible for pushing out melted filament through a nozzle, which then gets deposited onto a print bed to create the desired object. There are two main types of extruders – single extruder and dual extruder.

As the name suggests, single extruder printers can only use a single filament at any given time, while dual extruder printers can use multiple filaments simultaneously. In this article, we will be taking a closer look at dual drive extruders and discussing some of the advantages that they offer over single drive extruders.

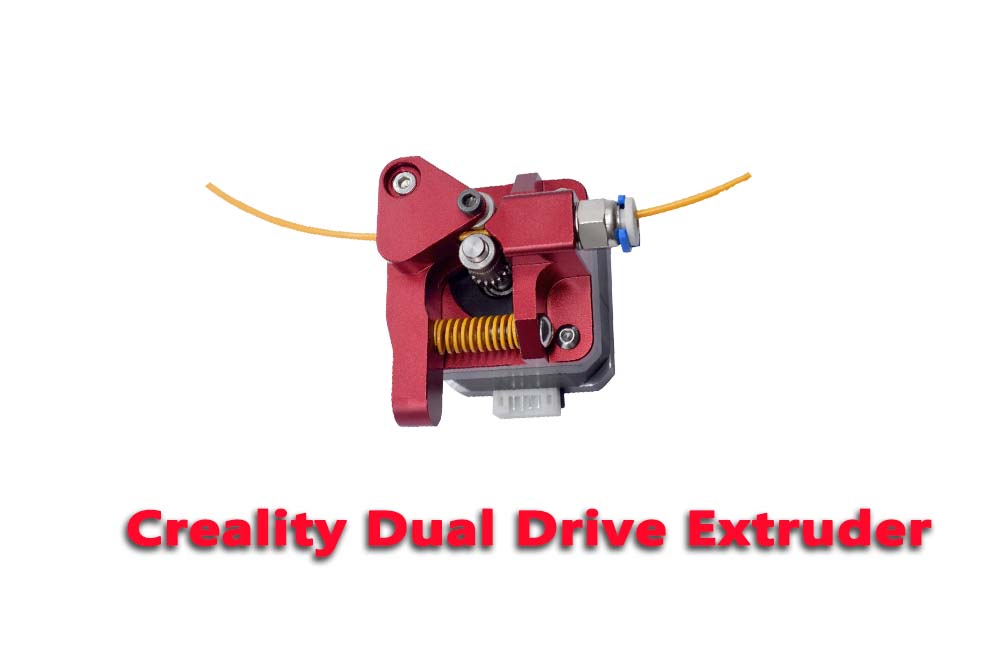

Dual Drive Extruders

Dual drive extruders are a type of dual extruder that uses two separate motors to drive the filament. This setup is different from the traditional dual extruder, which uses a single motor to drive both filaments. Dual drive extruders offer several advantages over traditional dual extruders, such as increased reliability, printing speed, and print quality.

ADVANTAGE NO: 01

One of the biggest advantages of dual drive extruders is the ability to print with multiple colors or materials. With a traditional dual extruder, you are limited to using only two filaments at any given time. However, with a dual drive extruder, you can use multiple filaments simultaneously, which allows for more flexibility in terms of what you can print.

Additionally, dual drive extruders are also more reliable than traditional dual extruders, as they have two separate motors. If one of the motors fails, the other one can still continue to function properly.

ADVANTAGE NO: 02:

Dual drive extruders are also faster than traditional dual extruders, as they have two separate motors. This means that both filaments can be driven at the same time, which results in a higher printing speed. Finally, dual drive extruders also offer better print quality than traditional dual extruders.

This is because with two separate motors, each filament can be controlled more accurately, which leads to better prints.

Disadvantages of Dual Drive Extruders

DISADVANTAGE NO: 01:

Although dual drive extruders offer several advantages over traditional dual extruders, they do have some disadvantages as well. The main disadvantages of dual drive extruders are their complexity and weight. Dual drive extruders are more complex than single drive extruders, as they have two separate motors which need to be controlled separately.

This can be a bit tricky for beginners and may take some time to get used to. Additionally, dual drive extruders are also heavier than single drive extruders, as they have two separate motors which add to the overall weight of the printer.

DISADVANTAGE NO: 02:

Dual drive extruders are also noisier than single drive extruders. This is because they have two separate motors which generate more noise. Finally, dual drive extruders are not as common as single drive extruders and are hence not available in all the printers. If you are looking for a dual drive extruder setup, then you may have to look harder than usual.

Function of dual extruders:

The dual extruder is a type of 3D printer that uses two extruders to print objects. This is in contrast to the single extruder, which can only use one filament at a time. The dual extruder has two separate motors, which drive the filaments independently.

This leads to several advantages over the single extruder, such as faster printing speed, better print quality and the ability to print with multiple colors or materials. However, the dual extruder is more complex and heavier than the single extruder and it also generates more noise.

It is not as common as the single extruder and is hence not available in all printers. If you are looking for a dual extruder setup, then you may have to look harder than usual.

Types of dual extruders:

There are several types of dual extruders available on the market. The most common type is the dual drive extruder, which uses two separate motors to drive the filaments. This setup is different from the traditional dual extruder, which uses a single motor to drive both filaments.

Dual drive extruders offer several advantages over traditional dual extruders, such as increased reliability, printing speed and print quality.

OTHER TYPES:

Other types of dual extruders include the geared extruder and the bowden extruder. The geared extruder uses two gears to drive the filament, while the bowden extruder uses a tube to guide the filament from the printer to the hot end.

Both of these types are less common than the dual drive extruder and are not available in all printers. If you are looking for a dual extruder setup, then you may have to look harder than usual.

Conclusion:

Dual extruders offer several advantages over single extruders, such as increased speed, print quality and the ability to print with multiple colors or materials. However, they are also more complex and heavier than single extruders and generate more noise.

Dual extruders are not as common as single extruders and are hence not available in all printers. If you are looking for a dual extruder setup, then you may have to look harder than usual.

FAQ’s:

1. What is a dual extruder?

A dual extruder is a type of 3D printer that uses two extruders to print objects. This is in contrast to the single extruder, which can only use one filament at a time. The dual extruder has two separate motors, which drive the filaments independently.

2. What are the advantages of a dual extruder?

The main advantages of a dual extruder are increased printing speed, better print quality and the ability to print with multiple colors or materials.

3. What are the disadvantages of a dual extruder?

The main disadvantages of a dual extruder are its complexity and weight. Dual extruders are more complex than single extruders and are also heavier. They also generate more noise than single extruders.

4. What printers support dual extruders?

Not all printers support dual extruders. The most common type of dual extruder is the dual drive extruder, which is available in some printers. Other types of dual extruders, such as the geared extruder and bowden extruder, are less common and are not available in all printers.