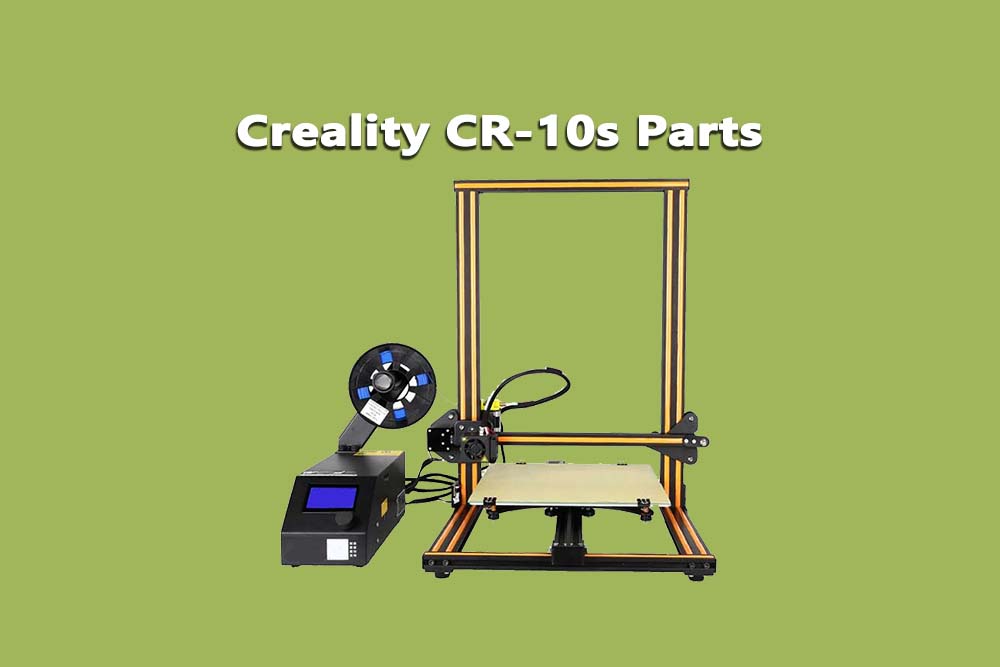

Parts of Creality CR-10s:

Electronics:

1. The control box is where all the magic happens. It’s responsible for interpreting g-code commands and turning them into electrical signals that move the motors. There are a few different types of controllers on the market, but the CR-10s uses an Arduino Mega 2560 with RAMPS 1.4 shield.

2. Power supply – this provides power to the controller and other electronics. For the CR-10s, you’ll need a 12V power supply that can provide at least 20 amps of current.

3. Stepper motors – these convert electrical pulses into mechanical movement, and are what actually drive the heated bed and extruder carriage along the linear rails. The CR-10s uses NEMA 17 stepper motors.

4. Heated bed – this keeps the build plate nice and warm, which helps with adhesion of the filament to the build surface. The CR-10s uses a 24V/400W heated bed.

5. Extruder – this is what melts the filament and deposits it onto the build plate. The CR-10s uses a Bowden-style extruder, which means that the motor that drives the filament is located in the control box, and the actual extruder head is mounted on the carriage. This style of extruder is more lightweight and compact, but can be more difficult to maintain than a direct-drive extruder.

6. Linear rails – these provide very smooth and precise movement for the carriage, ensuring that your prints come out looking great. The CR-10s uses 20mm aluminum extrusion for its linear rails.

7. Build plate – this is what the filament gets deposited onto. It’s typically made of glass or aluminum, and is heated in order to help with adhesion. The CR-10s uses a glass build plate.

8. Fans – these help to cool the electronics and heated bed, and also direct airflow over the print to help with cooling. The CR-10s has two fans: one for the electronics, and one for the hotend/heated bed.

9. Spool holder – this holds the spool of filament so that it can be fed into the extruder. The CR-10s has a spool holder that mounts to the side of the frame.

Mechanics:

1. Frame – this is the basic structure of the printer, and everything else mounts to it. The CR-10s uses aluminum extrusions for its frame, which provides good rigidity and stability.

2. X-axis linear rails – these provide very smooth and precise movement for the carriage, ensuring that your prints come out looking great. The CR-10s uses 20mm aluminum extrusion for its linear rails.

3. Y-axis linear rails – these provide very smooth and precise movement for the carriage, ensuring that your prints come out looking great. The CR-10s uses 20mm aluminum extrusion for its linear rails.

4. Z-axis lead screw – this is what moves the Z-axis up and down, and is responsible for the vertical movement of the build plate. The CR-10s uses an M8 lead screw with a trapezoidal nut.

5. X-axis carriage – this holds the extruder and carries it along the X-axis linear rails. The CR-10s uses a printed carriage that mounts to the aluminum extrusions.

6. Y-axis carriage – this holds the X-axis carriage and carries it along the Y-axis linear rails. The CR-10s uses a printed carriage that mounts to the aluminum extrusions.

7. Z-axis motor – this is what moves the Z-axis up and down, and is responsible for the vertical movement of the build plate. The CR-10s uses a NEMA 17 stepper motor.

8. X-axis lead screw – this is what moves the X-axis carriage along the linear rails, and is responsible for the horizontal movement of the extruder. The CR-10s uses an M5 lead screw with a trapezoidal nut.

9. Y-axis lead screw – this is what moves the Y-axis carriage along the linear rails, and is responsible for the horizontal movement of the extruder. The CR-10s uses an M5 lead screw with a trapezoidal nut.

Software:

1. slicing software – this converts a 3D model into g-code, which is a set of instructions that tells the printer what to do. The CR-10s uses Cura as its slicing software.

2. control software – this is what you use to send g-code to the printer, and also allows you to control all of the settings and parameters of the print. The CR-10s uses Repetier Host as its control software.

3. firmware – this is the low-level code that runs on the printer’s electronics, and controls all of the hardware. The CR-10s uses Marlin as its firmware.

4. host software – this is what you use to send g-code to the printer, and also allows you to control all of the settings and parameters of the print. The CR-10s uses Repetier Host as its host software.

Print quality:

1. Layer height – this is the thickness of each layer, and has a direct impact on the detail and overall smoothness of the print. The CR-10s can print at layer heights down to 0.1mm.

2. Line width – this is the width of the extruded filament, and has a direct impact on the detail and overall smoothness of the print. The CR-10s can extrude filament with a width down to 0.4mm.

3. Print speed – this is how fast the printer moves while printing, and has an indirect impact on the detail and overall smoothness of the print. The CR-10s can print at speeds up to 200mm/s.

4. Retraction distance – this is how much filament is pulled back into the extruder when the nozzle moves from one location to another, and has an indirect impact on the detail and overall smoothness of the print. The CR-10s can retract filament up to 4mm.

5. Travel speed – this is how fast the printer moves when it’s not printing, and has an indirect impact on the detail and overall smoothness of the print. The CR-10s can move at speeds up to 250mm/s.

Materials:

1. PLA – this is a versatile material that can be printed at low temperatures and does not require a heated bed. PLA is a good choice for beginners, and is the most popular material for 3D printing.

2. ABS – this is a strong material that can be printed at high temperatures, but requires a heated bed. ABS is commonly used for prototyping and industrial applications.

3. PETG – this is a strong material that can be printed at high temperatures, but requires a heated bed. PETG is commonly used for food-safe applications.

4. Nylon – this is a strong and durable material that can be printed at high temperatures, but requires a heated bed. Nylon is commonly used for mechanical parts and industrial applications.

5. TPU – this is a flexible material that can be printed at high temperatures, but requires a heated bed. TPU is commonly used for phone cases and other flexible applications.

It uses Cura as its slicing software, Repetier Host as its control software, and Marlin as its firmware. The CR-10s can print at speeds up to 200mm/s, and can move at speeds up to 250mm/s when it’s not printing. The CR-10s supports a wide range of materials, including PLA, ABS, PETG, nylon, and TPU.

FAQ’s:

1. What are the dimensions of the CR-10s?

The CR-10s has a build volume of 300x300x400mm.

2. What is the minimum layer height that the CR-10s can print at?

The CR-10s can print at layer heights down to 0.1mm.

3. What software does the CR-10s use?

The CR-10s uses Cura as its slicing software, Repetier Host as its control software, and Marlin as its firmware.

4. What is the maximum speed that the CR-10s can print at?

The CR-10s can print at speeds up to 200mm/s.

5. What is the maximum speed that the CR-10s can move at when it’s not printing?

The CR-10s can move at speeds up to 250mm/s.

6. What materials does the CR-10s support?

The CR-10s supports a wide range of materials, including PLA, ABS, PETG, nylon, and TPU.