What is fan?

A fan is a device used to create airflow. It can be powered by electricity, wind or even human power. Fans come in all shapes and sizes, from small desk fans to huge industrial fans.

What are the benefits of using a fan?

- There are many benefits of using a fan, including:

- Increased air circulation, which helps to keep you cool in summer months

- Improved air quality, as fans help to move polluted air away from your face

- Reduced energy costs, as fans can help to circulate cooled or heated air more efficiently

- Added comfort, as fans can help to alleviate feelings of warmth or humidity

How do I choose the right fan for me?

To choose the right fan for you, consider the following factors:

- – Size: Fans come in all shapes and sizes, so be sure to choose one that is the right size for your needs. A small desk fan may not be suitable for a large room, and a large industrial fan may be too powerful for a small office.

- – Function: Consider what you will be using your fan for. If you want to use it to cool down in summer, then you will need a different type of fan than if you want to use it to circulate air in winter.

- – Location: Where will you be using your fan? Fans can be used indoors or outdoors, but not all types of fans are suitable for both.

- – Budget: Fans can vary greatly in price, so be sure to set a budget before you start shopping.

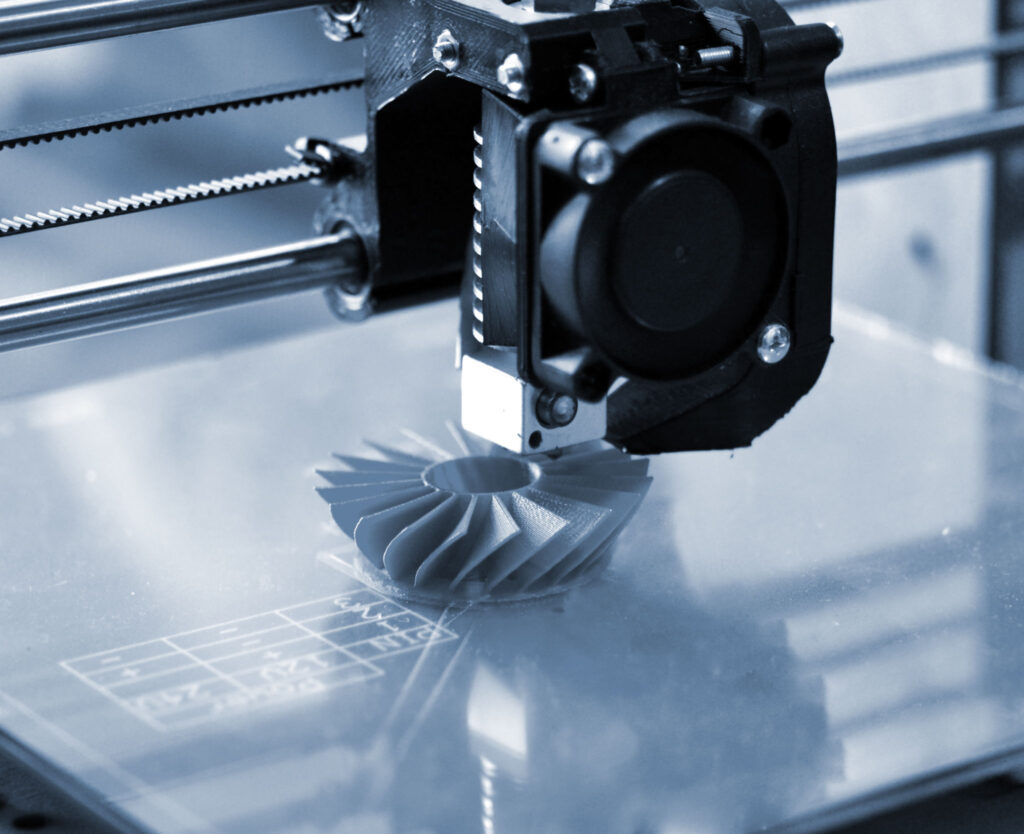

What is role of fan in creality?

The role of a fan in a 3D printer is to keep the extruder cooled. If the extruder becomes too hot, it can cause the filament to melt and clog the nozzle. A cooling fan helps to prevent this from happening.

How cooling fan works in creality?

A cooling fan works by blowing air over the extruder and dissipating the heat. This keeps the filament from melting and clogging the nozzle.

What are the benefits of using a cooling fan in creality?

There are many benefits of using a cooling fan in a 3D printer, including:

- Increased reliability, as the extruder is less likely to overheat and fail

- Improved print quality, as the filament is less likely to melt and cause defects

- Increased speed, as the extruder can operate at higher temperatures without risk of failure

- Reduced energy costs, as the printer does not have to work as hard to cool down the extruder

What are the drawbacks of using a cooling fan in creality?

There are some drawbacks to using a cooling fan in a 3D printer, including:

- Increased noise, as the fan can be noisy when it is running

- Reduced portability, as the fan adds weight and bulk to the printer

- Increased risk of breakage, as the fan can be broken if it is not handled carefully

- Increased cost, as the fan requires electricity to run.

Types of cooling fan in creality:

There are two main types of cooling fans for 3D printers: blower fans and radial fans.

Blower fans are the most common type of cooling fan. They work by blowing air over the extruder and dissipating the heat. Radial fans are less common, but they work in a similar way.

The main difference between blower fans and radial fans is that blower fans can be more difficult to install, as they need to be mounted on the side of the printer. Radial fans are easier to install, as they can be mounted on the top or bottom of the printer.

How to choose cooling fan for creality?

To choose the right cooling fan for your 3D printer, consider the following factors:

– Size: Fans come in all shapes and sizes, so be sure to choose one that is the right size for your needs. A small desk fan may not be suitable for a large printer, and a large industrial fan may be too powerful for a small printer.

– Type: Blower fans are the most common type of cooling fan, but radial fans can also be used. Consider which type of fan will be easier for you to install.

– Budget: Fans can vary greatly in price, so be sure to set a budget before you start shopping.

The bottom line

A cooling fan is an important part of any 3D printer, as it helps to keep the extruder cooled and prevents the filament from melting and clogging the nozzle. There are two main types of cooling fans: blower fans and radial fans. To choose the right fan for your needs, consider the size, type, and budget.

Blower fan vs Radial fan

The main difference between blower fans and radial fans is that blower fans can be more difficult to install, as they need to be mounted on the side of the printer. Radial fans are easier to install, as they can be mounted on the top or bottom of the printer. Blower fans are more common, but radial fans can also be used. Consider which type of fan will be easier for you to install.

How to install cooling fan?

Installing a cooling fan is relatively easy, but there are a few things to keep in mind:

– Be sure to choose a fan that is the right size for your printer. A small fan may not be suitable for a large printer, and a large fan may be too powerful for a small printer.

– Choose a fan that is the right type for your needs. Blower fans are more common than radial fans, but radial fans can also be used.

– Make sure the fan has a power cord and plug it into an outlet.

– Install the fan on the side of the printer using the included screws or brackets.

– If you are using a blower fan, make sure to install it in the correct direction. The air should be blowing over the extruder, not away from it.

– If you are using a radial fan, make sure to install it so that the air is blowing away from the extruder.

– Once the fan is installed, be sure to test it to make sure it is working properly.

3d printer cooling fan not working?

If your 3D printer’s cooling fan is not working, there are a few things you can do:

- Check the power cord and make sure it is plugged into an outlet.

- Check the fuse and make sure it is not blown.

- Check the switch and make sure it is turned on.

- Inspect the fan blades and make sure they are not damaged.

- Clean the fan blades and make sure they are free of debris.

- If the fan still does not work, you may need to replace it.

3d printer cooling fan noise:

If your 3D printer’s cooling fan is making noise, there are a few things you can do:

- Check the power cord and make sure it is plugged into an outlet.

- Check the switch and make sure it is turned on.

- Inspect the fan blades and make sure they are not damaged.

- Clean the fan blades and make sure they are free of debris.

- If the fan is still making noise, you may need to replace it.

FAQ’s:

How do I know if my 3D printer needs a cooling fan?

If your 3D printer does not have a cooling fan, the filament may melt and clog the nozzle. This can cause problems with printing. To avoid this, it is best to use a cooling fan.

How do I choose the right cooling fan for my 3D printer?

To choose the right cooling fan for your 3D printer, consider the following factors: size, type, and budget. Choose a fan that is the right size for your printer and that fits your budget.

Be sure to choose a fan that is the right type for your needs. Blower fans are more common than radial fans, but radial fans can also be used.

How do I install a cooling fan on my 3D printer?

Installing a cooling fan is relatively easy. Be sure to choose a fan that is the right size for your printer and the right type for your needs. The fan should have a power cord and should be plugged into an outlet. The fan can be installed on the side of the printer using screws or brackets.

If you are using a blower fan, make sure to install it in the correct direction. The air should be blowing over the extruder, not away from it. If you are using a radial fan, make sure to install it so that the air is blowing away from the extruder. Once the fan is installed, be sure to test it to make sure it is working properly.