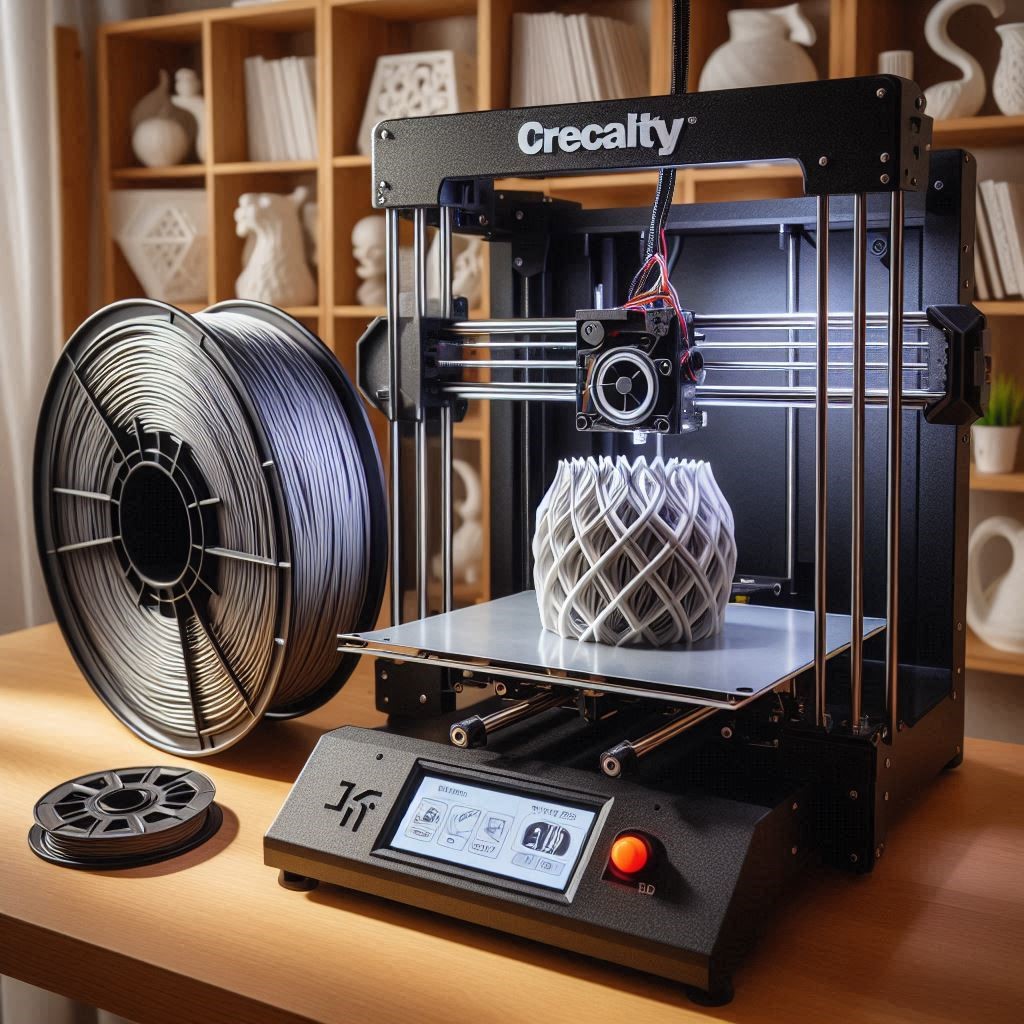

In the world of 3D printing, choosing the right filament is critical to achieving optimal results. While PLA and ABS are two of the most common filaments, another material gaining significant popularity is PETG (Polyethylene Terephthalate Glycol). As Creality 3D printers continue to dominate the desktop 3D printing market, understanding how to use PETG filament with these machines can help makers, engineers, and hobbyists unlock the full potential of their 3D prints.

In this article, we’ll explore Creality 3D printer PETG filament, its benefits, its use cases, and practical tips for printing with this material. Whether you’re a beginner or an experienced 3D printing enthusiast, this guide will help you understand why PETG is a go-to material for many and how to make the most of it with your Creality 3D printer.

What is PETG Filament?

PETG is a modified version of PET (Polyethylene Terephthalate), a plastic that’s commonly used for packaging and plastic bottles. The addition of glycol to the base polymer makes PETG easier to print with and more flexible, offering a strong, durable, and impact-resistant material. It retains the best qualities of PET, such as its excellent chemical resistance, while adding new features that make it ideal for 3D printing applications.

Compared to PLA (Polylactic Acid), PETG offers a higher level of durability and is more heat resistant, making it a preferred choice for parts that need to withstand mechanical stress and higher temperatures. In contrast to ABS, PETG is less prone to warping and doesn’t release harmful fumes during printing.

Why Choose PETG for 3D Printing?

There are several reasons why PETG is becoming a top choice for 3D printing, especially among users of Creality 3D printers. Let’s explore some of the key advantages of using PETG filament.

1. Excellent Durability and Strength

PETG is a very strong filament, offering better mechanical properties than PLA. It can handle greater stresses without cracking or breaking, making it ideal for functional parts and prototypes. The filament has a high tensile strength and excellent impact resistance, making it suitable for items that need to endure physical wear and tear.

2. Good Heat Resistance

While not as heat-resistant as ABS, PETG still performs well under moderate heat. It can typically withstand temperatures of up to 80-85°C (176-185°F) without deforming. This makes it a great choice for creating parts that may be exposed to moderate heat in everyday use, such as automotive components or certain electronic housings.

3. Low Shrinkage and Warping

Unlike ABS, PETG has very low shrinkage and minimal warping during the printing process. This means that prints made with PETG are more likely to stay flat on the print bed and produce better results with less need for post-processing. This property also makes it ideal for larger prints, as you won’t need to worry as much about warping issues that can plague other filaments.

4. Food Safe and Chemical Resistant

PETG is naturally non-toxic, making it safe for creating food contact items, medical prototypes, and items that might come into contact with sensitive environments. It also offers good resistance to a wide range of chemicals, including diluted acids and bases, which can be important in industrial applications.

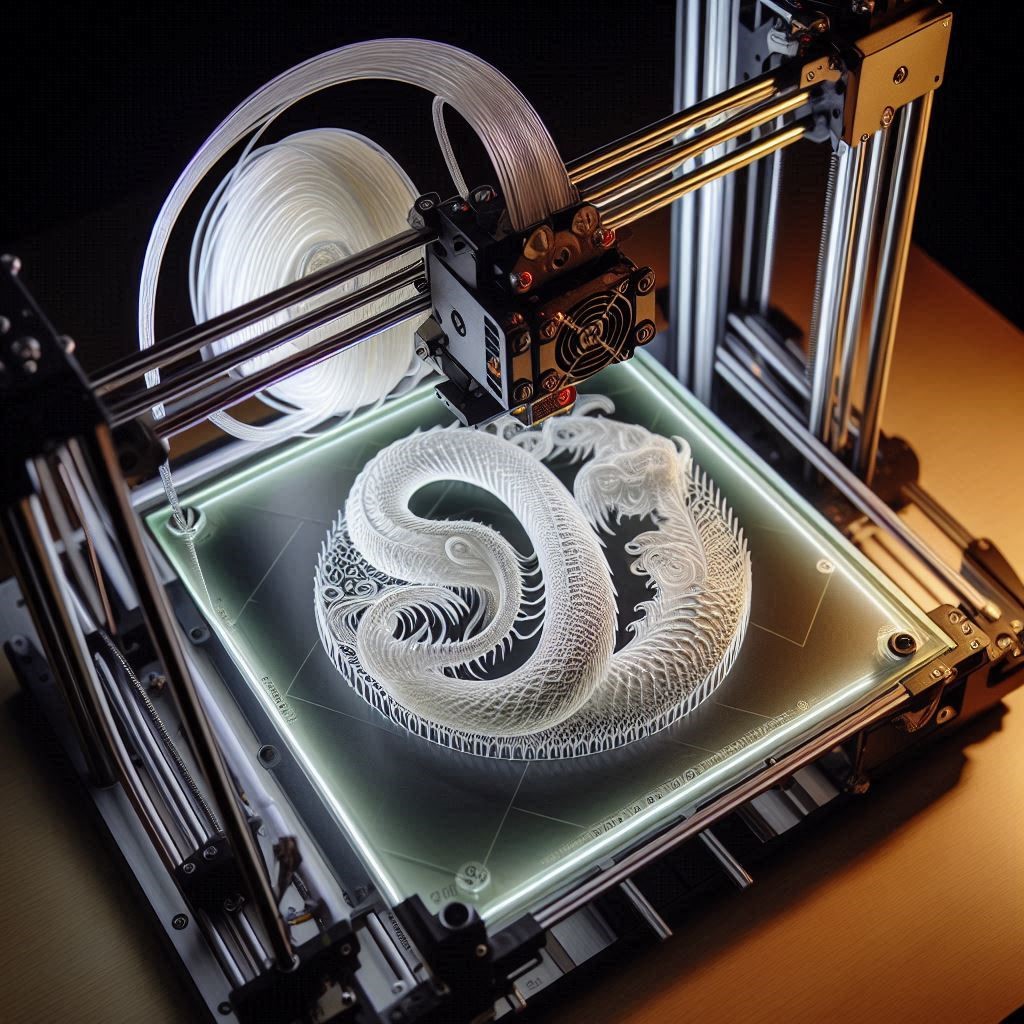

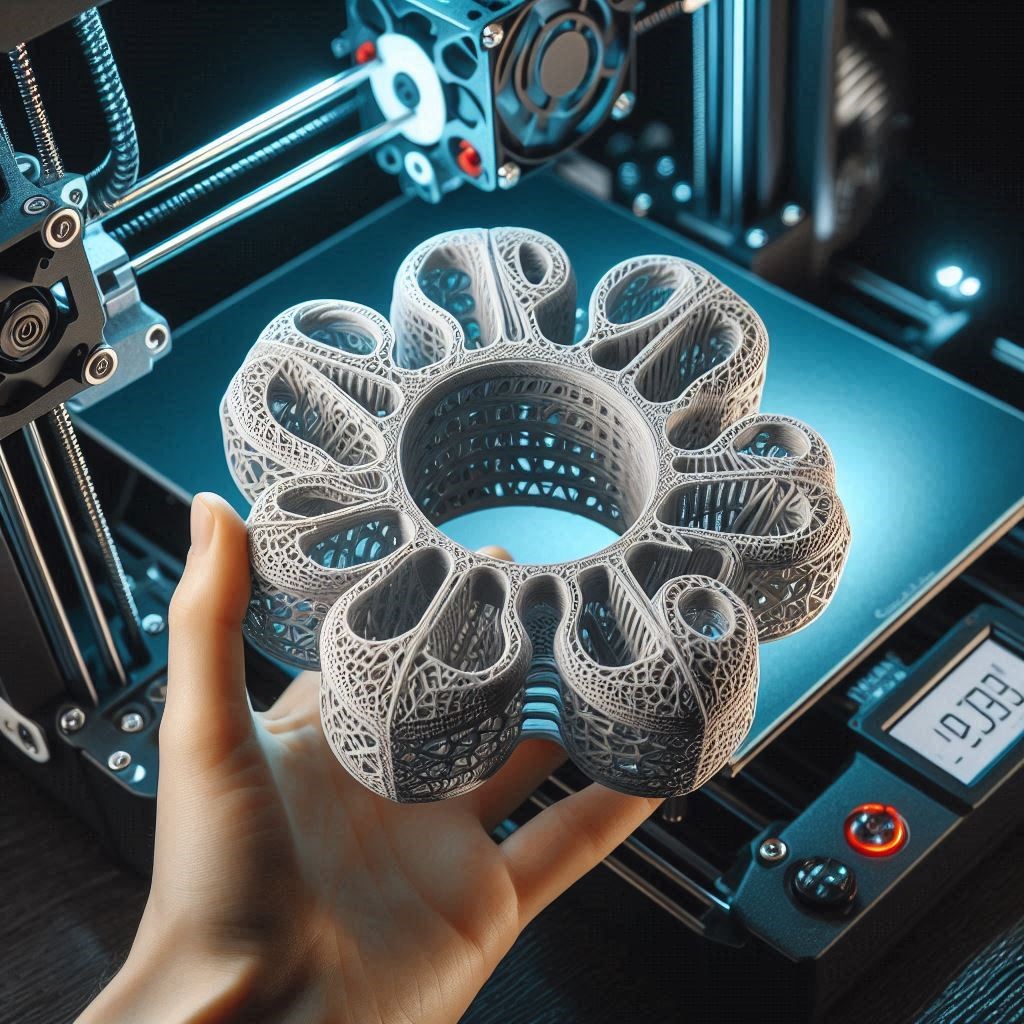

5. Crystal Clear or Translucent Prints

One of the standout features of PETG is its ability to produce crystal clear or translucent prints. This makes it a good option for creating visually appealing objects, like custom cases or decorative items, where transparency or clarity is important.

6. Environmentally Friendly (Partially)

While not biodegradable like PLA, PETG is considered more environmentally friendly than other filaments like ABS. PETG can be recycled, reducing its overall environmental impact compared to non-recyclable materials. That said, proper disposal and recycling practices are still important.

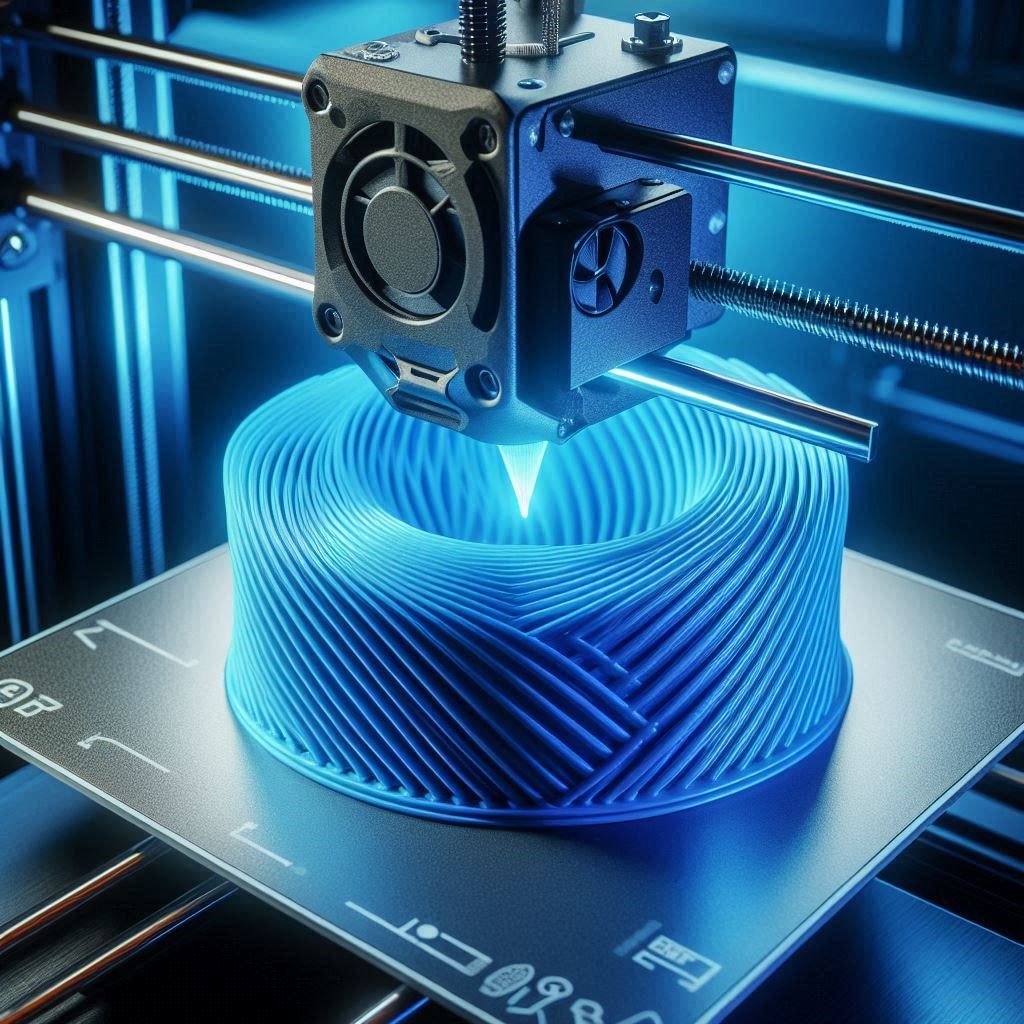

How to Print with Creality 3D Printer PETG Filament

1. Choosing the Right Creality Printer

Creality 3D printers, such as the Ender 3, Ender 5, and CR-10 series, are widely known for their reliability and affordability. Most Creality printers can handle PETG filament, but a few things must be considered for the best results.

- Hotend Temperature: PETG prints best when the hotend is heated to a range of 230-250°C. Be sure your Creality printer’s hotend is capable of reaching and maintaining these temperatures. The Ender 3 V2, for example, is a great choice for PETG because it comes with an upgraded all-metal hotend that can handle higher extrusion temperatures.

- Heated Bed: Although PETG has a lower warping tendency, a heated bed is still crucial to ensure good adhesion and prevent bending during the print. A bed temperature of 70-80°C is optimal for most PETG filaments.

- Print Speed: The recommended print speed for PETG is typically between 30 to 50 mm/s. Printing too fast can result in poor layer adhesion, while printing too slow can cause overheating and clogging.

2. Preparing the Bed for PETG

PETG adheres well to a heated bed, but getting the first layer right is key to a successful print. Here’s how to prepare your print bed:

- Use a Good Adhesion Surface: PETG sticks well to surfaces like PEI, BuildTak, or even painter’s tape. If you’re using glass, applying a light layer of glue stick or hairspray can improve adhesion and prevent prints from coming loose.

- Bed Leveling: Proper bed leveling is essential when using PETG. If the bed is too far from the nozzle, the filament won’t stick. If it’s too close, it may result in poor extrusion or nozzle clogging. Always check the bed level before starting your print, especially when switching filaments.

3. Fine-Tuning the Print Settings

To get the best results when printing with PETG on your Creality 3D printer, here are a few print settings to adjust:

- Extrusion Multiplier: PETG has a tendency to ooze, so a slightly lower extrusion multiplier (typically 0.9 to 1.0) may help reduce stringing and improve print quality.

- Retraction Settings: PETG can exhibit stringing, especially when printing with finer details. Adjusting your retraction settings is essential. Start with a retraction distance of around 4-6mm and a retraction speed of 25-40mm/s for best results.

- Cooling: PETG generally prints best with low to moderate cooling. Too much cooling can cause the filament to warp, while too little cooling can result in poor layer adhesion. Start with a cooling fan setting of around 30-40% and adjust based on the results.

4. Troubleshooting Common PETG Printing Issues

Even though PETG is relatively easy to print with, there are a few common issues that users may face. Here are some troubleshooting tips:

- Stringing and Oozing: This is a common issue with PETG due to its tendency to ooze from the nozzle. You can reduce stringing by fine-tuning retraction settings and adjusting your print speed. Lowering the extruder temperature slightly can also help.

- Adhesion Problems: If your print isn’t sticking well to the bed, check the bed temperature and ensure your bed is clean. Using a light layer of glue stick or hairspray on a glass bed can help improve adhesion.

- Layer Separation: If layers seem to separate or the print feels weak, consider increasing the print temperature slightly to improve layer bonding.

Conclusion

PETG filament is a fantastic material for 3D printing, offering a unique balance of strength, flexibility, and ease of use. Whether you’re creating prototypes, functional parts, or aesthetically pleasing designs, PETG delivers solid results across a wide range of applications. For Creality 3D printer users, PETG is a perfect filament choice for durability and quality, especially when combined with proper print settings and careful calibration.

By understanding the properties of PETG, optimizing your printer settings, and troubleshooting common issues, you can achieve professional-grade prints with your Creality 3D printer. Experiment with this versatile filament, and soon you’ll see why PETG is becoming a go-to material for 3D printing enthusiasts around the world.