Introduction to Creality Ender 3 Parts

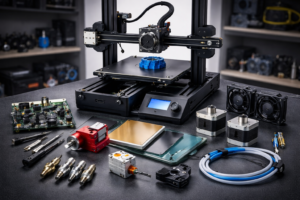

The Creality Ender 3 is one of the most popular desktop 3D printers in the world, trusted by beginners, hobbyists, and professionals alike. One major reason for its success is the wide availability of creality ender 3 parts, which makes the printer highly customizable, easy to repair, and affordable to maintain.

Whether you are replacing worn-out components, fixing a sudden failure, or upgrading for better print quality, understanding each part of the Ender 3 is essential. This guide walks you through every major component in simple terms, helping you make confident decisions without technical confusion.

Understanding the Creality Ender 3 Ecosystem

Why the Ender 3 Is So Popular

The Ender 3 gained popularity because it offers:

- A strong aluminum frame

- Open-source compatibility

- Low entry cost

- Huge community support

Its modular design allows users to swap parts without replacing the entire machine.

Stock vs Aftermarket Components

Stock parts are designed for basic functionality and cost savings. Aftermarket parts often focus on:

- Higher durability

- Improved accuracy

- Better heat resistance

Both options work well depending on your needs and budget.

Core Mechanical Parts Explained

Frame and Aluminum Extrusions

The rigid aluminum frame keeps the printer stable during operation. A bent or loose frame can cause layer shifting and uneven prints.

Belts, Pulleys, and Motion System

Belts control movement on the X and Y axes. Proper tension is critical for accuracy.

X-Axis Components

- Timing belt

- Carriage plate

- V-slot wheels

Y-Axis Components

- Bed carriage

- Y-axis belt

- Stepper motor

Z-Axis Lead Screw and Motor

The lead screw raises and lowers the gantry. Regular lubrication reduces binding and noise.

Extruder and Filament System

Stock Plastic Extruder

The original plastic extruder works but may crack over time with frequent use.

Metal Extruder Upgrades

Metal extruders provide:

- Stronger filament grip

- Longer lifespan

- More consistent extrusion

Bowden Tube and Couplers

The PTFE tube guides filament smoothly. Worn couplers can cause under-extrusion and clogs.

Hotend and Nozzle Assembly

Hotend Components Breakdown

Heater Block and Thermistor

These regulate temperature. A faulty thermistor can cause heating errors.

Heat Break and Heat Sink

They prevent heat from traveling upward, avoiding filament jams.

Nozzle Types and Materials

Common nozzle materials include:

- Brass (standard use)

- Stainless steel (food-safe)

- Hardened steel (abrasive filaments)

Print Bed and Build Surface Parts

Heated Bed

The heated bed improves first-layer adhesion and reduces warping.

Glass, PEI, and Magnetic Beds

Each surface has benefits:

- Glass: smooth finish

- PEI: excellent adhesion

- Magnetic: easy print removal

Electronics and Control Components

Mainboard

Silent mainboards reduce motor noise and improve print quality.

Stepper Motors

These motors control movement. Failure often shows as skipped steps.

Power Supply Unit

A stable power supply ensures consistent heating and motor performance.

Cooling and Fan Systems

Hotend Cooling Fan

Keeps the heat sink cool and prevents clogs.

Part Cooling Fan

Improves print detail by cooling freshly extruded plastic.

Sensors, Switches, and Safety Parts

Endstop Switches

They tell the printer when an axis has reached its limit.

Bed Leveling Sensors

Auto bed leveling sensors save time and improve first-layer consistency.

Common Replacement vs Upgrade Parts

| Replacement Parts | Upgrade Parts |

|---|---|

| Nozzles | All-metal hotend |

| PTFE tubes | Silent mainboard |

| Belts | Metal extruder |

| Fans | Auto bed leveling sensor |

How to Choose the Right Parts

When selecting parts, consider:

- Compatibility with your Ender 3 model

- Print materials you use

- Your skill level

- Long-term reliability

Buying from reputable sellers or the official Creality store is always recommended. You can also explore trusted community resources like the official Creality website: https://www.creality.com

Maintenance Tips for Long-Term Performance

- Clean the nozzle regularly

- Check belt tension monthly

- Lubricate the Z-axis lead screw

- Inspect wiring for wear

- Keep firmware updated

Proper care reduces downtime and extends part life.

Frequently Asked Questions (FAQs)

1. How often should Ender 3 parts be replaced?

It depends on usage, but nozzles and PTFE tubes typically need replacement every few months.

2. Are metal extruders worth it?

Yes, they are more durable and provide better filament control.

3. Can I upgrade parts without technical skills?

Many upgrades are beginner-friendly with basic tools and guides.

4. Do aftermarket parts affect warranty?

They may, depending on the seller. Always check warranty terms.

5. What parts improve print quality the most?

Nozzles, bed surfaces, and cooling upgrades have the biggest impact.

6. Where can I buy reliable Ender 3 parts?

Official stores, trusted online retailers, and well-reviewed community vendors.

Conclusion

Understanding and maintaining creality ender 3 parts is the key to unlocking the full potential of your 3D printer. From mechanical components to electronics and upgrades, every part plays a role in print quality, reliability, and user experience. With the right knowledge and regular maintenance, your Ender 3 can deliver consistent, high-quality prints for years to come.