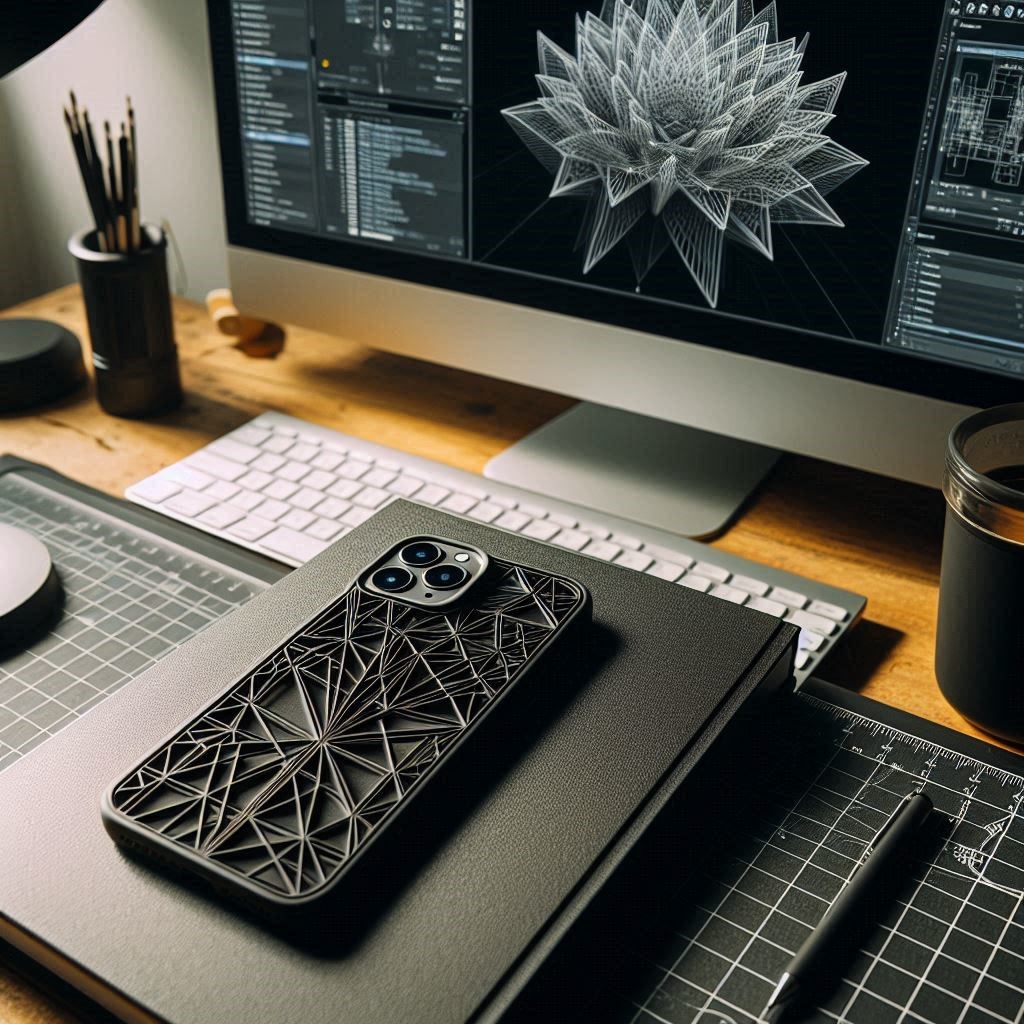

The iPhone 13 has captured the hearts of tech enthusiasts and everyday users alike with its sleek design, powerful performance, and advanced camera capabilities. However, as with any smartphone, protecting it is paramount. While there are countless phone cases available on the market, one of the most innovative and personalized options is to 3D print your own iPhone 13 case.

This blog post will explore the benefits of 3D printing a phone case, how to design and print your own, and tips for achieving the best results.

Why 3D Print Your Own iPhone 13 Phone Case?

3D printing offers numerous advantages over traditional phone case manufacturing. Here are some compelling reasons to consider creating your own case:

1. Customization

One of the most significant benefits of 3D printing is the ability to customize your phone case to match your personal style. Whether you prefer a sleek minimalist look, vibrant colors, or unique patterns, 3D printing allows you to bring your vision to life. You can add your name, favorite quotes, or even intricate designs that reflect your personality.

2. Perfect Fit

Off-the-shelf cases may not always provide a perfect fit, especially if you have added accessories like a screen protector. By designing your own case, you can ensure that it accommodates all ports, buttons, and camera features seamlessly.

3. Material Choices

When 3D printing, you have the freedom to select materials based on your needs. You can choose flexible filaments for shock absorption, rigid materials for maximum protection, or even biodegradable options for eco-friendly choices. This flexibility allows you to prioritize aesthetics or functionality as desired.

4. Cost-Effective

3D printing can be a cost-effective solution, especially if you already own a printer. While commercial cases can range from $10 to $50 or more, printing your own can be significantly cheaper, particularly when using common filaments like PLA.

5. Learning Experience

Creating a 3D printed phone case can be an excellent project for those looking to develop their design and printing skills. It provides an opportunity to learn about CAD software, slicing programs, and the intricacies of 3D printing.

Designing Your iPhone 13 Phone Case

Before you can print your case, you’ll need a design. There are several ways to approach this:

1. Using CAD Software

If you have experience with computer-aided design (CAD), you can create your own model from scratch. Popular software options include:

- TinkerCAD: A user-friendly online platform ideal for beginners.

- Fusion 360: A more advanced program that offers extensive tools for detailed designs.

- Blender: Great for those interested in more artistic or complex designs.

When designing, consider the following:

- Dimensions: Ensure your design matches the iPhone 13’s dimensions (146.7 x 71.5 x 7.65 mm) to guarantee a proper fit.

- Button and Port Access: Include cutouts for buttons, ports, and cameras.

- Ventilation: If your design is more enclosed, consider adding ventilation holes to avoid overheating.

2. Downloading Pre-Made Models

If designing isn’t your forte, you can find a plethora of free and paid phone case models online. Websites like Thingiverse, MyMiniFactory, and Cults offer a variety of options, often customizable to fit the iPhone 13. When downloading, ensure the model is specifically labeled for the iPhone 13 to avoid sizing issues.

3. Modifying Existing Designs

You might find a design you love but wish to tweak it. Using CAD software, you can import existing models and modify them to suit your preferences. This could involve changing dimensions, adding unique features, or personalizing the design.

Preparing for 3D Printing

Once you have your design ready, it’s time to prepare for printing:

1. Choose the Right Material

Selecting the right filament is crucial for achieving the desired outcome. Common options include:

- PLA: Easy to print, biodegradable, and available in many colors. However, it’s less durable than other options.

- PETG: A great balance of strength and flexibility, making it ideal for phone cases.

- TPU: A flexible filament that provides excellent shock absorption, perfect for protective cases.

- ABS: Durable and heat-resistant, but requires a heated bed and proper ventilation.

2. Slice Your Model

After choosing your material, use slicing software (like Cura or PrusaSlicer) to convert your 3D model into G-code, which the printer can understand. Key settings to consider include:

- Layer Height: A smaller layer height (0.1 mm) will yield finer detail but take longer to print.

- Infill Density: Higher infill provides more strength but increases material usage. For a phone case, 20-30% infill is usually sufficient.

- Print Speed: Slower speeds often result in better quality, especially for detailed models.

3. Test Print

Before committing to a full print, consider creating a small test print to check the fit and aesthetics. This step can save time and material in the long run.

Printing Your Phone Case

Now that everything is set up, it’s time to start printing!

1. Printer Setup

Ensure your printer is clean and calibrated. Check that the print bed is level and that the nozzle is clear.

2. Monitoring the Print

During the printing process, keep an eye on the model to catch any potential issues early. Watch for layer adhesion problems, warping, or filament jams.

3. Post-Processing

Once your print is complete, carefully remove it from the print bed. You may need to trim any excess material or supports, especially if your model has intricate details. Common post-processing techniques include:

- Sanding: Smooth out rough edges for a more polished look.

- Painting: Use spray paint or acrylics to add color and style to your case.

- Sealing: Consider applying a sealant to protect the finish and improve durability.

Tips for Successful 3D Printing

To ensure the best results with your iPhone 13 phone case, keep these tips in mind:

- Experiment with Settings: Don’t be afraid to tweak your printer settings based on your results. Every printer is different, and finding the right balance may take time.

- Use a Quality Printer: If you’re serious about 3D printing, consider investing in a reliable printer. The Elegoo Neptune 4 Pro, Creality Ender 3, or Prusa Mini are excellent options for enthusiasts.

- Join a Community: Engage with online forums and communities dedicated to 3D printing. Websites like Reddit, Facebook groups, and dedicated forums can provide support, inspiration, and feedback.

- Stay Informed: 3D printing technology is continually evolving. Stay updated with the latest trends, materials, and techniques to enhance your skills and projects.

- Keep It Fun: The beauty of 3D printing lies in its creativity. Don’t hesitate to explore unusual designs or ideas. If a case doesn’t turn out as planned, view it as a learning opportunity.

Conclusion

3D printing your own iPhone 13 phone case offers a unique blend of creativity, personalization, and practicality. By taking advantage of design software, online resources, and the latest printing technologies, you can create a case that not only protects your device but also reflects your individuality.

Whether you choose to design from scratch, modify existing models, or experiment with materials, the process of creating a custom phone case can be rewarding and enjoyable. So fire up your printer, unleash your creativity, and protect your iPhone 13 in style!